3 sets of 15TPD Semi-Continuous Waste Tyre Recycling Pyrolysis Machines in Brazil Project Features

- Project address:Brazil

- Daily process capacity:45TPD

- Processed raw material:waste tyre

- Manufacturer:Xinxiang Doing Renewable Energy Equipment Co., Ltd

- Installation time :2024.12

3 sets of 15TPD Semi-Continuous Waste Tyre Recycling Pyrolysis Machines in Brazil Project Description

In December 2024, our company successfully installed three sets of 15TPD semi-continuous waste tyre recycling pyrolysis machines at a client’s facility in Brazil. This installation marks a significant milestone in our expansion across South America, showcasing our commitment to providing efficient and sustainable solutions for tire recycling.

Semi-continuous waste tyre recycling pyrolysis machine in Brazil

Client Background

The client, a well-established company in the tire recycling industry, was already operating a batch waste tyre recycling pyrolysis machine at their facility. However, they faced challenges with low efficiency and limited output. To meet growing demand and improve processing efficiency, the client decided to upgrade their existing setup and sought a more advanced solution that would maximize production while maintaining environmental sustainability. After careful evaluation, they chose to purchase the waste tyre recycling pyrolysis machine from us Henan Doing Company due to its superior efficiency, robust performance and favorable cost.

DOING semi-continuous waste tyre recycling pyrolysis machine for sale

Why the Client Chose DOING Waste Tyre Recycling Pyrolysis Machine

The Brazil client’s primary concern was increasing production efficiency. They wanted a system that could handle a larger volume of tires while delivering high-quality output in a cost-effective manner. Our semi-continuous waste tyre recycling pyrolysis machines were chosen for their ability to operate with minimal downtime, high fuel efficiency and consistent throughput.

Additionally, the client emphasized the importance of factory production details, professionalism, and after-sales support. Henan Doing factory, with its large production capacity, extensive experience in handling bulk orders, and a reputation for high-quality manufacturing, made us a reliable partner. Furthermore, we offered excellent after-sales services and technical support, ensuring the client would have continuous assistance throughout the operation of the system. And we have exported and installed many pyrolysis machines in American countries, such as the United States of America, Mexico, Colombia, Brazil, Argentina, Bolivia, Peru, Colombia, Venezuela.

DOING waste tyre recycling pyrolysis machine projects

Key Benefits of the Semi-Continuous Waste Tyre Recycling Pyrolysis Machine

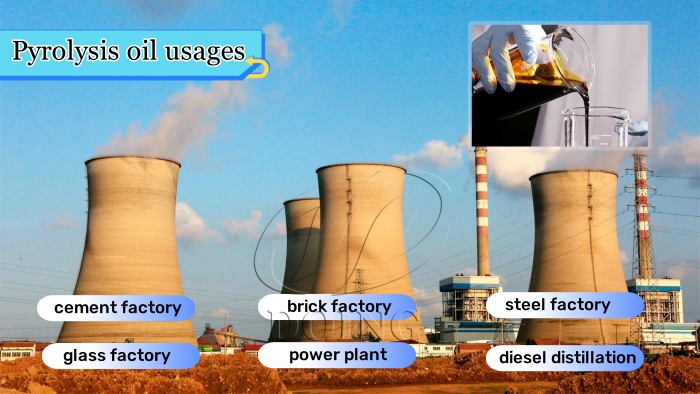

The design of semi-continuous waste tyre recycling pyrolysis machines installed in Brazil designed by Henan Doing Company allows for higher processing efficiency and greater flexibility, enabling the client to continuously feed tires into the system without halting operations. This results in increased productivity and reduced operational costs. The machine's advanced features ensure maximum resource recovery from waste tyre, producing valuable byproducts such as bio-oil, syngas, and carbon black, which can be used for various applications, from fuel production to industrial use.

Waste tyre recycling pyrolysis machine product application

Our commitment to quality, professional expertise and dedicated customer support made us the top choice for purchasing pyrolysis machines. With numerous successful installations all around the world, we are confident that our pyrolysis machines will help the client achieve significant improvements in their used tire/plastic/oily sludge recycling operations.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd