DOING waste plastic to fuel pyrolysis machine product introduction

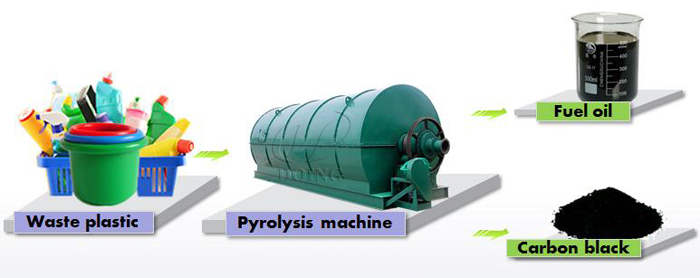

Plastic pollution is called white pollution. The increasing amount of plastic waste has brought severe environmental challenges to the world. At this time, pyrolysis technology came into being. This pyrolysis technology can not only alleviate environmental problems, but also recycle waste into treasure, recycling plastic waste such as PE, PP, PS, ABS, etc. into fuel oil, carbon black, syngas for reuse. This article mainly introduces DOING pyrolysis machine of waste plastic to fuel from types, process, product applications, profit analysis.

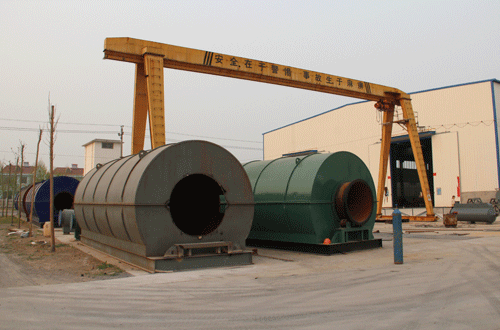

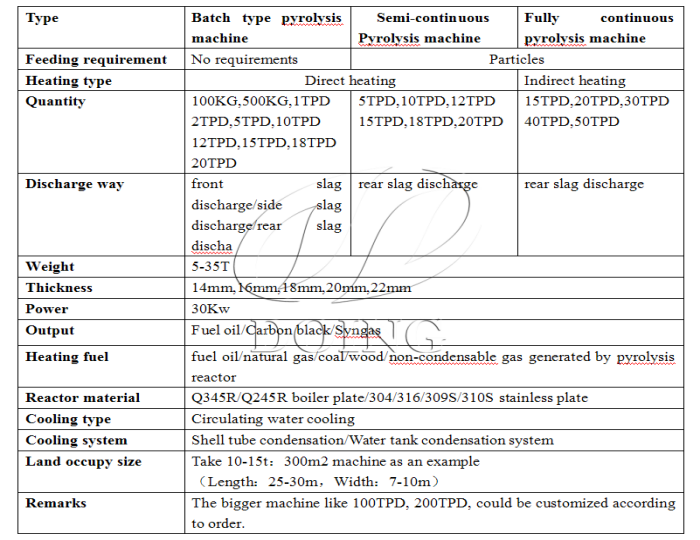

There are three types of DOING waste plastic to fuel pyrolysis machine

Introduction of DOING three types of waste plastic to fuel pyrolysis machine

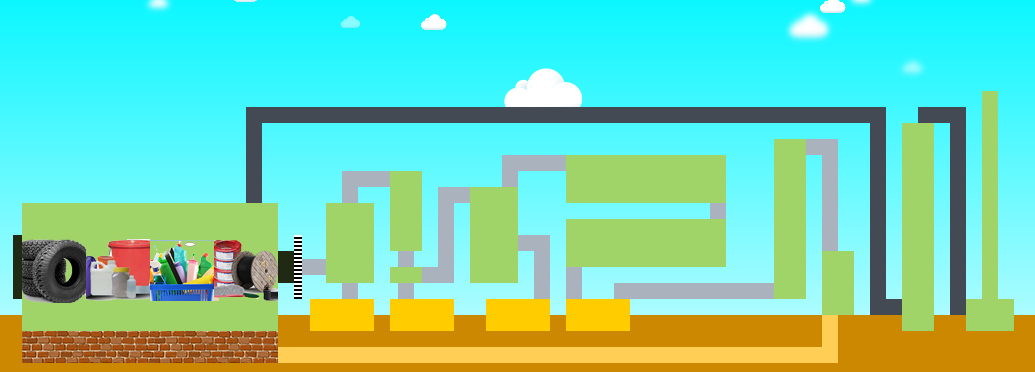

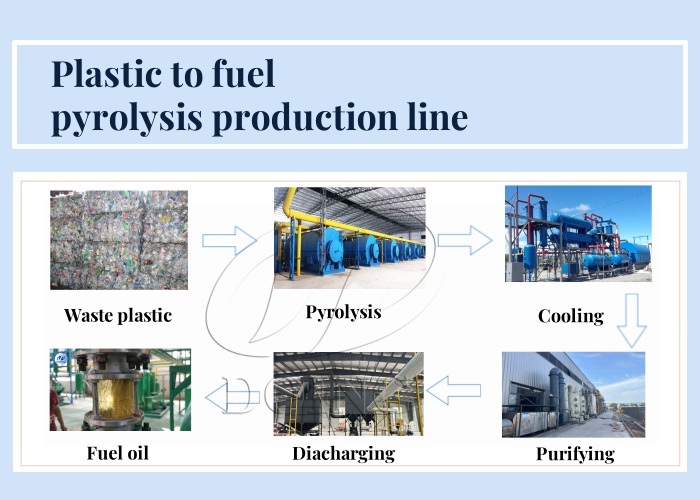

The process of DOING waste plastic to fuel pyrolysis machine

DOING waste plastic to fuel pyrolysis machine process

1.Feeding the waste plastic: Feeding the plastic into the batch type pyrolysis machine by labor or auto-feeder: Hydraulic. Feeding the plastic particles into the continuous type pyrolysis machine by screw conveyor.

2.Pyrolysis the waste plastic to oil gas: Heat the pyrolysis reactor with heating fuel to recycle the waste plastic into fuel oil, carbon black and syngas. For waste plastic, the optimal cracking temperature is around 320°C.

3.Cooling the oil gas to oil: The oil and gas produced are transported through a pipeline to the condensation system, where they are cooled and condensed into liquid oil. The oil is then stored in a temporary storage tank for further use.

4.Treatment of exhaust gas: The waste gas and waste dust generated enters the environmental protection purification device treatment system: exhaust gas purification treatment device and flue gas purification treatment device to remove.

5.Collection of carbon black : The batch type waste plastic pyrolysis machine collects the carbon black at the low temperature, the continuous type waste plastic pyrolysis machine collects the carbon black at the high temperature.

The product of DOING waste plastic to fuel pyrolysis machine application

The product application of recycling waste plastic pyrolysis machine

1.Fuel oil: It is mainly used in steel mills, glass factories, boiler heating, heavy oil generators, cement plants, etc.

2.Carbon black: It is mainly used for ball burning and fine grinding. Finely ground powder can be used in new tires, rubber soles, pigments, etc.

3.Syngas: The non-condensable gas, can be used as fuel to heat reactors.

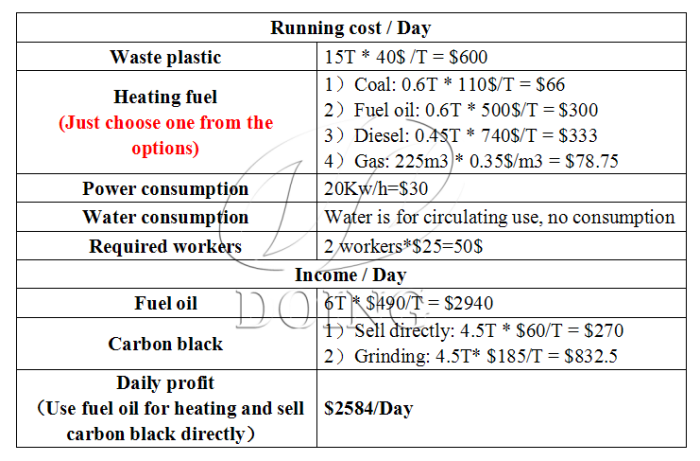

The profits of DOING waste plastic to fuel pyrolysis machine(Takes 15TPD waste plastic to fuel pyrolysis machine as an example )

DOING waste plastic to fuel pyrolysis machine profits analysis

DOING waste plastic to fuel pyrolysis machine has been exported in more than 100 countries, such as Ecuador, Vietnam, India, France, Spain, Italy, Switzerland, Egypt, Canada, Colombia, Mexico, Australia, etc. Here is an operation video of the semi-continuous type DOING pyrolysis machine of waste plastic to fuel purchased by a Ecuadorian customer for your reference:

If you want to gain profits through recycling plastic waste to fuel such as PE, PP, PS, ABS, etc. Please contact us, all departments work together surely to provide you with one-stop high quality service from R&D, design, production sales and after sales of DOING pyrolysis machine of waste plastic to fuel.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd