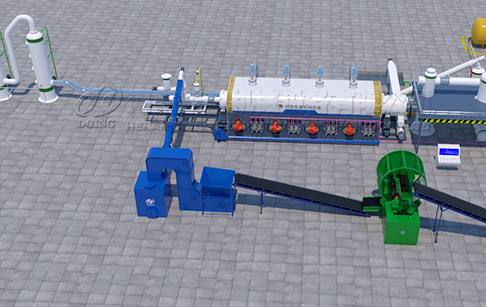

Oil sludge recovery pyrolysis machine for sale product introduction

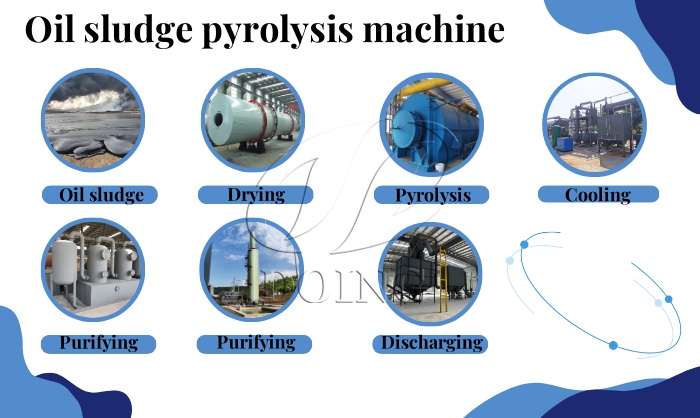

Pyrolysis technology is a popular and profitable treatment way for waste oil sludge. The waste oil sludge recovery pyrolysis machine is used to turn oil sludge into three products: pyrolysis oil, solid residue and syngas in a high temperature and oxygen-free environment to achieve resource recovery.

Oil sludge recovery pyrolysis machine

DOING waste oil sludge pyrolysis machine can recover many kinds of waste oil sludge generated from petroleum refinery machines or the petrochemical industry, such as coal tar residue, oil-based rock cuttings, drilling cuttings, oil field sludge, ship sludge, ground sludge, refinery sludge, tank bottom sludge, ground oil spills and other oil-containing sludge.

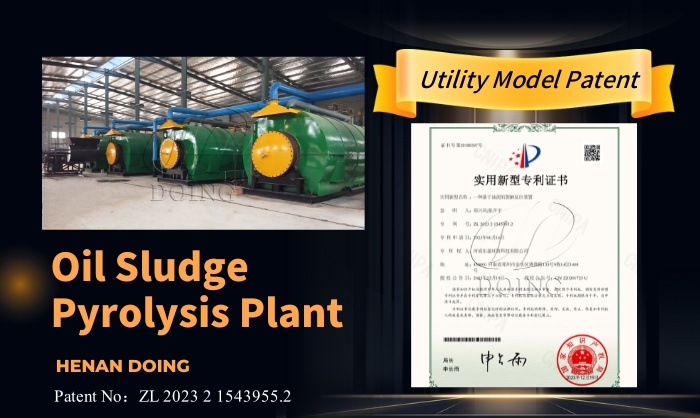

Model patent of DOING oil sludge pyrolysis plant

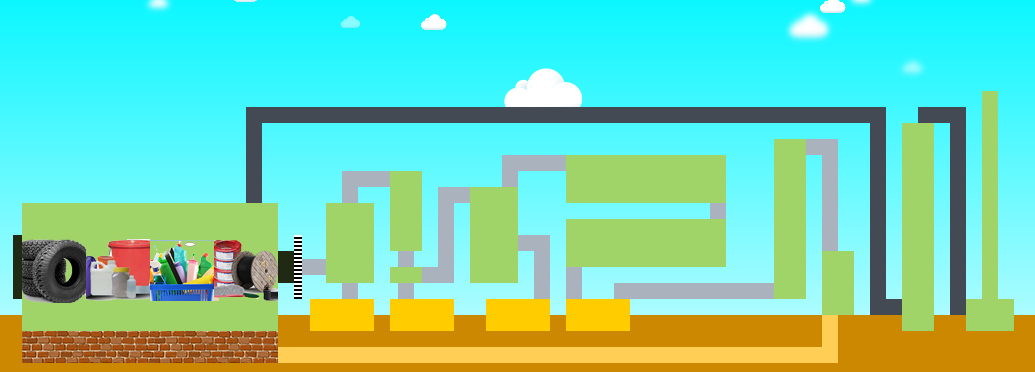

The deatailed waste oil sludge recovery pyrolysis process flow is: oil sudge dehydration --- feeding --- pyrolysis --- oil gas cooling --- gas cleaning and recovery for heating --- exhuast gas purification --- slagging. After this pyrolysis process, you can get the recovered fuel oil, solid residue and syn-gas for sale or reusing.

Waste oil sludge recovery pyrolysis process

Compared with traditional oil sludge treatment methods, such as incineration, landfill, etc., pyrolysis oil sludge technology has significant advantages:

1. Economic value: The pyrolysis oil produced after processing can be sold to heavy industries such as glass factories, steel factories, porcelain factories, etc as fuel. The waste soil produced after processing can be sold to construction companies for backfilling and building construction.

2. High treatment efficiency: This technology can complete the treatment of oil sludge in a short time, greatly improving the treatment efficiency. Through pyrolysis process, the oily sludge can be effectively converted into valuable products, reducing the processing cycle and floor space.

3. Environmental value: Equipped with a dust collector to achieve fully enclosed operation, without dust leakage during the operation. Equipped with exhuast gas purification and desulfurization tower to remove sulfur dioxide from flue gas to meet environmental emission standards.

Environmental devices of oil sludge recovery pyrolysis machine

Therefore, more and more investors select the pyrolysis machine to recover waste oil sludge. Based on different customers' requirements, our engineer team has designed different types and capacities of pyrolysis machines for oil sludge recovery. There are two types of DOING oil sludge recovery pyrolysis machines for sale according to the operating status: batch-type pyrolysis machine and semi-continuous type pyrolysis machine. Here are the specific capacities and parameters of oil sludge recovery pyrolysis machines:

| Type | Batch-type pyrolysis machine | Semi-continuous type pyrolysis machine |

| Raw material | oil sludge | |

| Product | fuel oil, solid residue, syngas | |

| Capacity | 1TPD,2TPD5TPD,10TPD,12TPD,15TPD18TPD,20TPD | 5TPD,10TPD,12TPD,15TPD |

| Thickness | 14mm,16mm,18mm20mm,22mm | 14mm,16mm,18mm20mm,22mm |

| Weight | 5-35T | |

| Power | 30Kw | |

| Heating type | Direct heating | |

| Heating fuel | fuel oil/natural gas/coal/wood | |

| Reactor material | Q345R/Q245R boiler plate/304/316/309S/310S stainless plate | |

| Cooling type | Circulating water cooling | |

| Cooling system | Shell tube condensation/Water tank condensation system | |

| Land occupy size | Take 10-15t:300m2 machine as an example(Length:25-30m,Width:7-10m) | |

| Remarks | The bigger machine like 100TPD, 200TPD, could be customized according to order. | |

Batch type oil sludge recovery pyrolysis machine needs to be shut down after finishing per batch of oil sludge pyrolysis process and final products collection, completing a cycle of activities in an average of 22 hours. The equipment dimensions and processing capacity of semi-continuous oil sludge recovery pyrolysis machine are basically the same as those of the batch type. In comparison, semi-continuous pyrolysis machine effectively saves cooling time and achieves the production efficiency of three batches in two days.

Note: DOING provides oil sludge recovery pyrolysis machine customized services, which can create the best equipment configuration plan based on oil sludge state, water content, oil content and other characteristics, including feeders, reactor main furnaces of different materials, thicknesses and specifications, anti-sludge coking and proportioning devices, environmental protection equipment that meets local environmental protection standards, etc.

Waste oil sludge pyrolysis machine in China

Till now, China-Henan Doing Company has installed many successful oil sludge recovery pyrolysis plants all over the world, such as China, Malaysia, Colombia, Canada, etc.

We got many good feedbacks of the stable equipment operation and good services, and there are customers continuously re-order machines from us. If you are looking for high quality oil sludge recovery pyrolysis plant for sale, please inquire DOING!

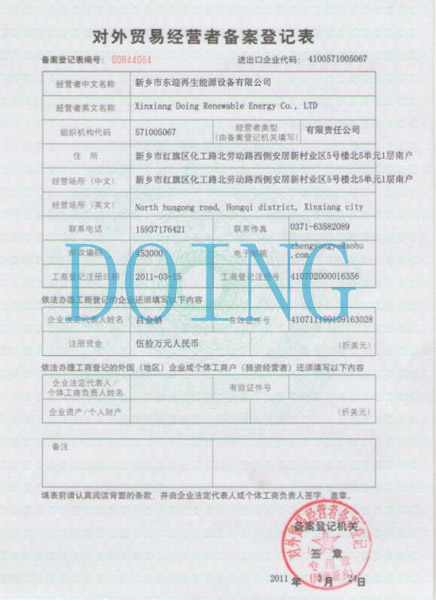

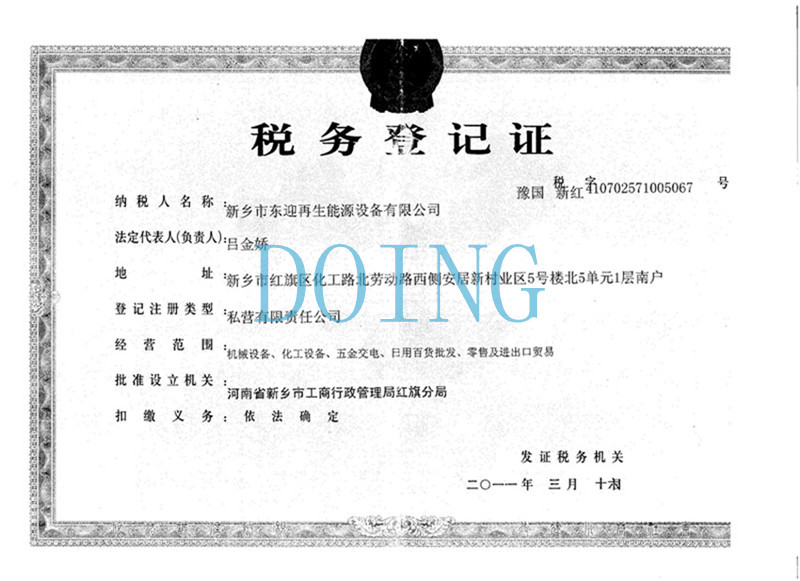

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd