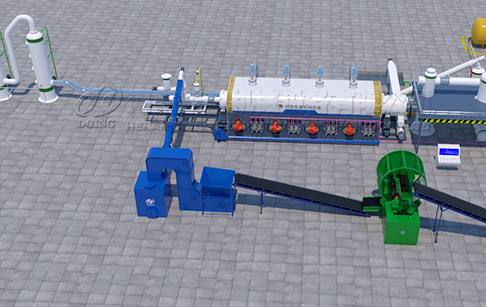

Tyre/Plactic/Rubber to oil recycling process pyrolysis plant product introduction

Waste tyre/plastic/rubber pyrolysis plant

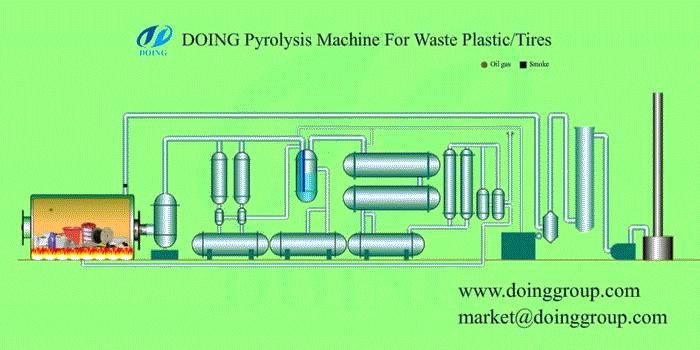

Waste tyre to oil pyrolysis plant is a set of environmental protection equipment, mainly using high temperature pyrolysis chemical reaction, the process of pyrolysis waste tire into combustible oil, carbon black and steel wire under high temperature and high pressure. The working of DoingGroup's Tyre/Plactic/Rubber to oil recycling process is as follows:

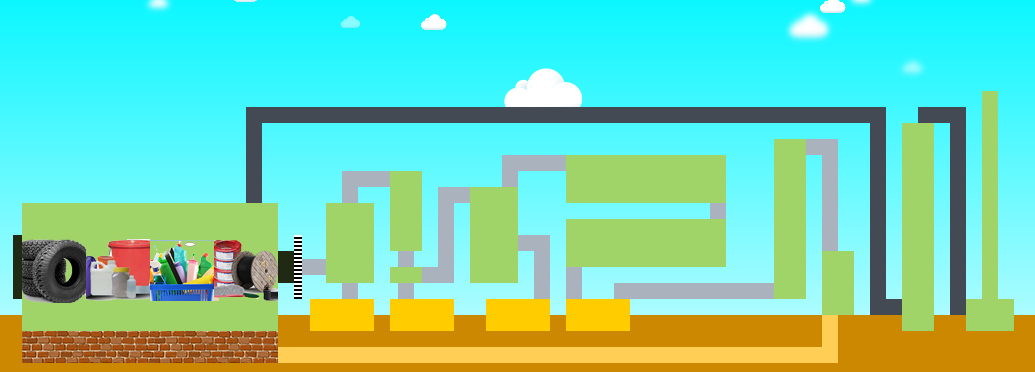

Tyre/Plactic/Rubber to oil recycling working process

1. The waste tire/plastic/rubber is fed into the reactor via an automatic feeding device.

2. The reactor is heated. When the temperature rises to 200 degrees, heavy oil and gas are cracked.

3. The cracked oil and gas enters the condensing system and is liquefied into heavy oil and falls into the oil tank.

4. The dedusting and deodorization of the heavy oil in the oil tank will eventually result in a combustible oil.

5. When the temperature in the reactor is cooled to below 40°C, the carbon black in the furnace will be discharged through the underground sealing device to avoid secondary pollution to the environment.

Tyre/Plactic/Rubber to oil recycling whole process is environmental

The entire Tyre/Plactic/Rubber to oil recycling process is designed in strict accordance with the European and American environmental assessment standards. Will not cause any pollution to the environment!

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd