Pyrolysis plastic to diesel fuel machine product introduction

Introduction to Pyrolysis Plastic to Diesel Fuel Machine-Innovative Waste Plastic Recycling Solution

In today's world, plastic waste management is an urgent global issue, with millions of tons of plastic waste ending up in landfills and oceans every year. Our Pyrolysis Plastic to Diesel Fuel Machine offers an innovative and environmentally-friendly solution by converting waste plastics (excluding PVC and PET) into valuable diesel fuel, promoting sustainable recycling and reducing plastic pollution.

Pyrolysis plastic to diesel fuel machine adopts one advanced technology called pyrolysis, refining or distillation, which takes advantage of high temperature and heat the plastic oil to working temperature by using fuel oil, gas, coal etc. as fuel materials.

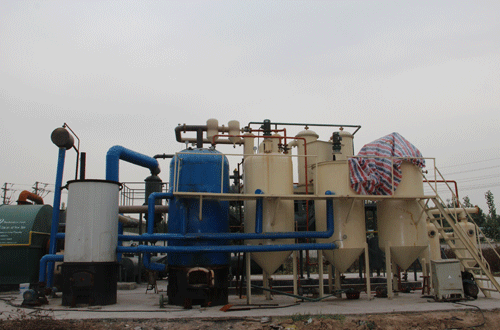

Pyrolysis plastic to diesel fuel machine

Through changing forms of the oil from liquid state to gaseous state and then from gaseous state to liquid state, the pyrolysis distillation technology can successfully remove the particles, colloidal matter, acid and odour from plastic oil by acid-alkali/sold catalyst treatment and filtration.

By using our state-of-the-art equipment, you can recycle waste plastic into a resource that can be used for energy, reducing both plastic waste and the reliance on conventional fossil fuels.

Pyrolysis plastic to diesel fuel working process

1. Feed the waste plastic raw materials into the pyrolysis reactor, and then heat the pyrolysis reactor to extract the oil gas.

2. Oil gas will go through professional industrial vertical/horizontal condensors for cooling into liquid plastic pyrolysis oil

3. Pump waste plastic oil into distillation reactor by oil pump.

4. Heat the distillation reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out.

Finally, we get qualified diesel fuel with a clean and transparent color and a qualified smell. Having high economic values, these diesel oil can be widely used in low speed engines and diesel generators such as digging machines, road roller, loading machines, trucks, ships, and so on.

Two Equipment Solutions for Plastic to Diesel Fuel Conversion

We offer two specialized equipment solutions to meet the varying needs of different clients. Choose from two equipment solutions, both offering high performance and scalability for sustainable waste plastic management.

Solution 1. Plastic to Diesel Pyrolysis Distillation Machine

Waste plastic to diesel fuel pyrolysis distillation machine

The Plastic to Diesel Pyrolysis Distillation Machine consists of two main components:

Pyrolysis Machine: This machine breaks down waste plastics into pyrolysis oil through the process of thermal decomposition.

Pyrolysis Oil Distillation Machine: After the pyrolysis process, the oil is further refined to produce high-quality diesel fuel.

This solution is highly versatile and suitable for processing a wide range/size of plastic types. The Pyrolysis Distillation Machine comes in different configurations, including batch and semi-continuous models, to accommodate various production needs. With flexible processing capacities and compatibility with different plastic forms and sizes, it is an ideal solution for diverse recycling operations.

Key Features:

Multiple machine configurations (batch or semi-continuous)

Suitable for various plastic types and forms (mixed plastic, big size or shredded plastic particles, etc.)

High customization options based on production capacity (capacity vary from 100kg to 14+Ton per set)

2. Plastic to Diesel Integrated Machine

Plastic to diesel fuel integrated machine

The Plastic to Diesel Integrated Machine offers a fully automated solution for middle/large-scale operations. This machine combines both pyrolysis and distillation processes into one integrated system, resulting in a more streamlined and efficient production process.

However, the Integrated Machine requires pre-shredded plastic input and is suitable for businesses that need higher automation and are dealing with uniform feedstock. Due to its higher automation and integrated design, this solution typically comes with a higher upfront cost but offers enhanced productivity and reduced manual labor.

Key Features:

High automation and integration for continuous operation

Requires shredded plastic feedstock

Higher initial investment but efficient and streamlined processing

Applications of Pyrolysis Plastic to Diesel Fuel

With the growing demand for renewable energy sources, converting plastic waste to diesel offers a cleaner alternative to traditional petroleum products.

Diesel Fuel Production: The main application of the pyrolysis process is producing fuel from waste plastics for industrial uses (using as high calorific value industrial heating fuel for steel/brick/china/glass/mill factories, etc), and the refinery fuel---diesel for further applications such as transportation (trucks/ships/boats/or other heavy machinery), and diesel generators.

Pyrolysis plastic to diesel fuel applications

Why Choose Henan DOING Pyrolysis Plastic to Diesel Fuel Machines?

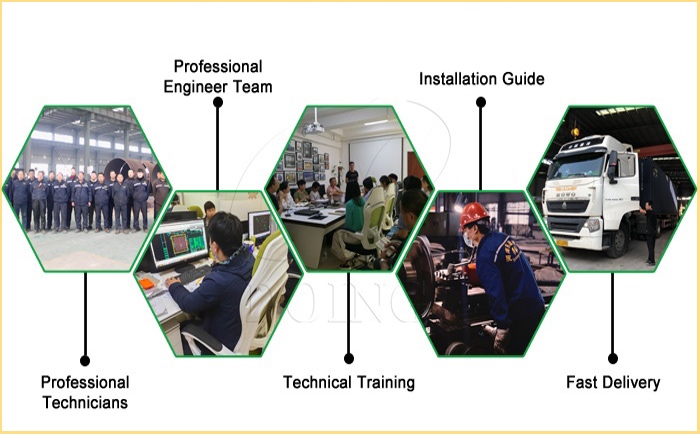

1. Proven Technology: We offer industry-leading pyrolysis distillation technology for efficient and reliable plastic-to-diesel conversion.

2. Customizable Solutions: Whether you need a small-scale batch solution or a large-scale integrated system, our machines can be tailored to your specific needs.

3. Eco-Friendly: Our machines are equipped with multi-stage environmental protection devices, ensuring that no additional industrial wastewater is generated and that gas emissions meet standards.

4. Global Reach: With our international expertise, we are able to support clients worldwide with installation, training and after-sales services.

Services of DOING pyrolysis plastic to diesel fuel machine manufacturer

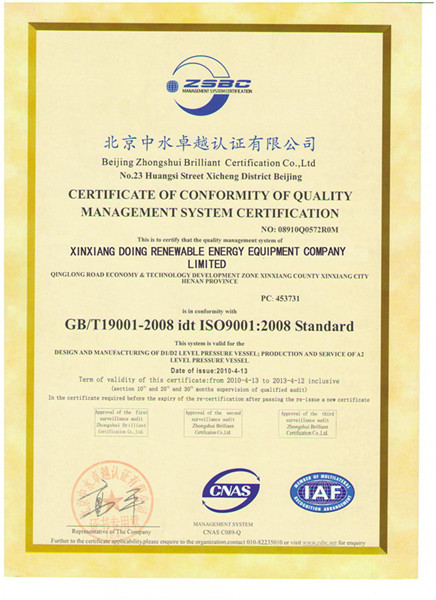

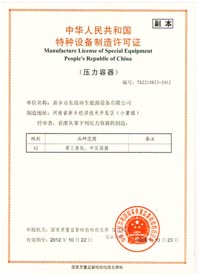

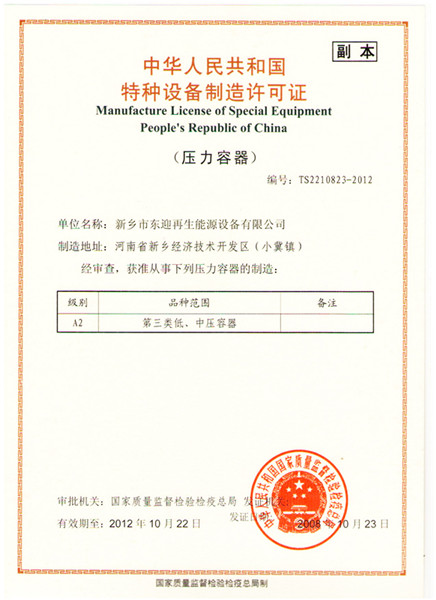

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd