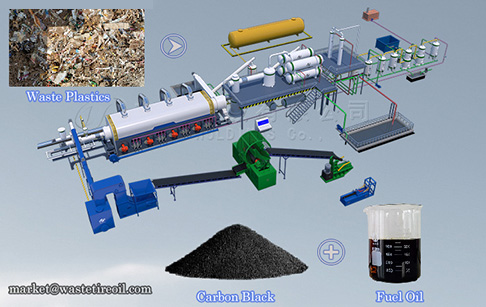

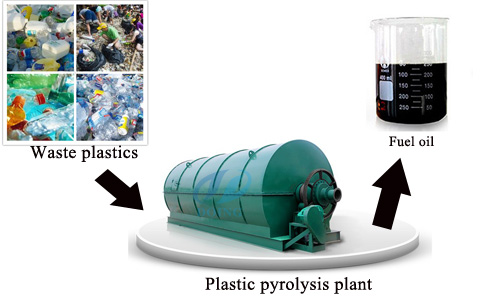

Waste old plastic pyrolysis plant product introduction

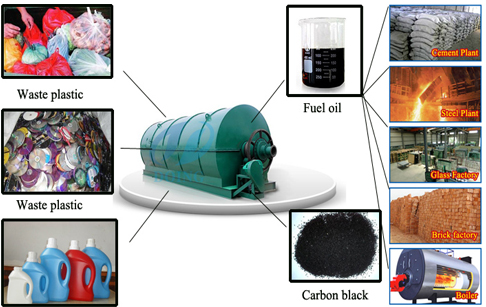

Waste old plastic pyrolysis plant is used to convert the waste plastic to oil gas and liquid oil for fuel. The systems use a continuous liquefaction technology alongside a unique catalytic breakdown process that turns waste materials into gases and liquids. The final product of the pyrolysis plant can be used in glass factory, cement factory and so on.

The major advantage of the process is that the plastic pyrolysis plant can deal with a wide range of waste plastics without any pollution and extremely high efficiency. Compared with dumped or incineration the oil plastic pyrolysis plant will convert the waste plastic to oil without any pollution.

Environmental advantages:

Old plastic pyrolysis plant technology reduces the volume of waste that is sent to landfills.

The process not only eliminates the emissions of harmful gases when the waste plastic burned, the plant itself will discharge nearly no emissions to the environment.

Old plastic pyrolysis plant technology provides a good alternative energy to petroleum based crude oil.

The pyrolysis plant will reduce the government cost to deal with the waste plastic. So the pyrolysis plant is beneficial to the society.

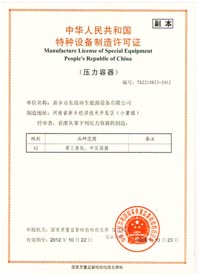

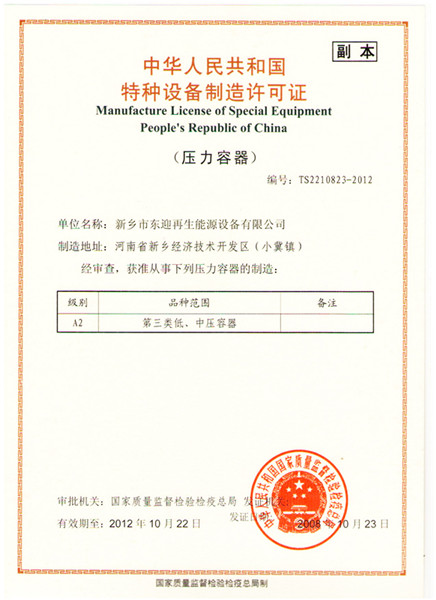

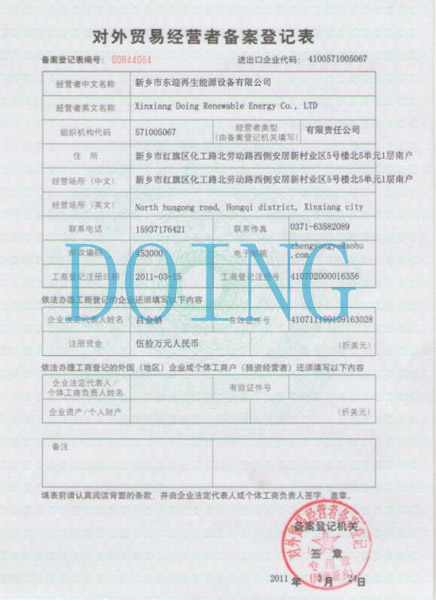

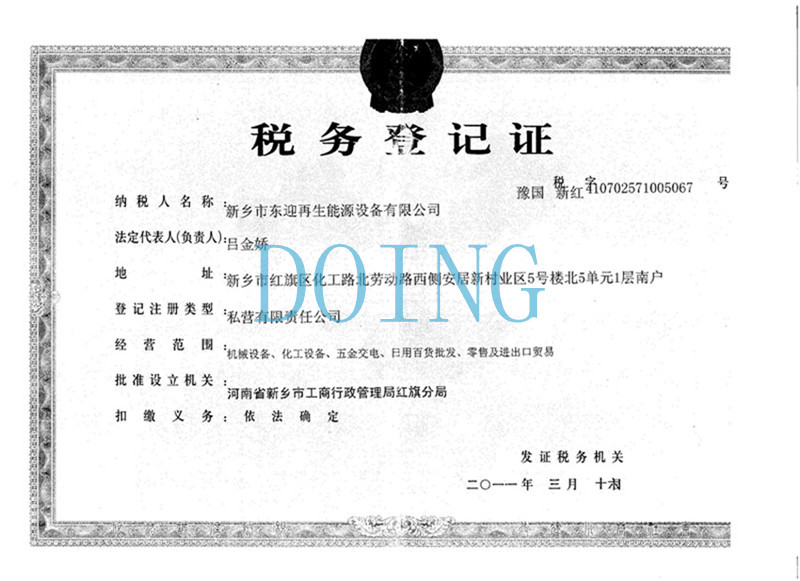

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd