Industry news / DATE:2023/10/5

Normally, there are four ways of plastic recycling: burning, landfilling, granulation and pyrolysis.

| Plastic burning | Cause serious air pollution and damage human health |

| Plastic landfilling | Difficult to decompose and cause serious soil pollution |

| Plastic granulation | Have strict requirements about types and materials of plastics, can’t effectively recycle most waste plastics |

| Plastic pyrolysis | Recycle waste plastics to fuel oil environmentally friendly, obtain huge profits ; |

So compared with plastic burning, plastic landfilling and plastic granulation, plastic pyrolysis is the more applicable way of plastic recycling.

DOING waste plastic pyrolysis machine for sale

While as the top manufacturer of waste plastic pyrolysis machine, owning over 13 years' manufacturing and installing experience, DOING has cooperated with many customers with our waste plastic pyrolysis machines. Next we will have a detailed introduction about DOING waste plastic pyrolysis machine:

Point One: working principal of the waste plastic pyrolysis machine

Waste plastics are usually made up of hydro-carbon polymers; in the high temperature and oxygen-free environment, the large molecules of waste plastics will be broken into smaller molecules. That is, the waste plastics will be recycled to fuel oil, carbon black and combustible gases.

Point Two: working process of the waste plastic pyrolysis machine

Put the waste plastics into the waste plastic pyrolysis machine and heat the reactor, when the temperature reaches between 280°C and 320°C, the oil gas will come out; after going through the cooling system, we can obtain fuel oil; then we can collect other useful products-carbon black and combustible gas.

Here is another small point that you need to pay attention to: not all waste plastics are suitable for waste plastic pyrolysis machines, such as the PVC and PET plastics are not suitable. But if the PVC and PET content is not much, less than 10%, then that’s okay.

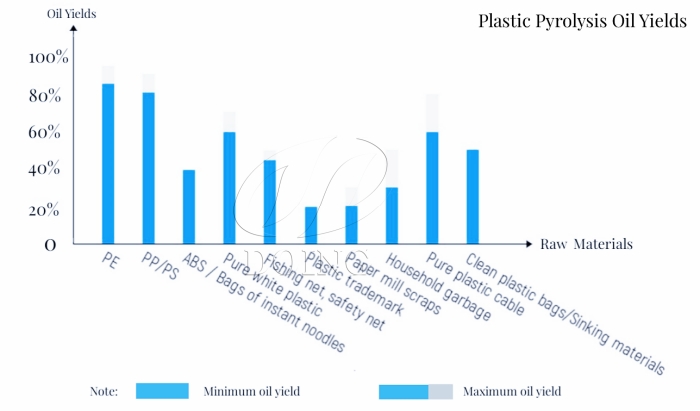

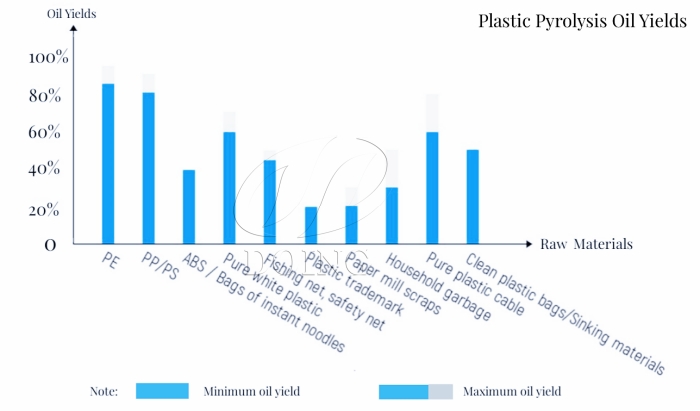

Oil yields of various waste plastics

Point Three: advantages of DOING waste plastic pyrolysis machine

1. Turn waste to treasure: with the waste plastic pyrolysis machine, we can recycle plastic waste to useful products, which have wide applications and large markets.

Fuel oil can be used as fuel energy in cement factories, steel factories, glass factories or heavy oil power plants to generate electricity; carbon black can be used as fuel energy or make new products, such as rubber tires, shoe soles and paints; combustible gas can be used as energy to heat the pyrolysis reactor to save fuel costs or transport to other spaces as fuel energy.

2. High environmental protection and high safety

DOING waste plastic pyrolysis machines are equipped with some environmental protection systems and safety devices. For example, our tail-gas cleaning system and dedulfurization tower can fully purify the exhaust gas to meet the high requirements about emission in various regions; and our patented device-Negative pressure vacuum device to fully extract the oil gas in the reactor to enhance working safety and avoid accidents.

Safety devices of DOING waste plastic pyrolysis machines

3. Multiple types and capacities for your reference

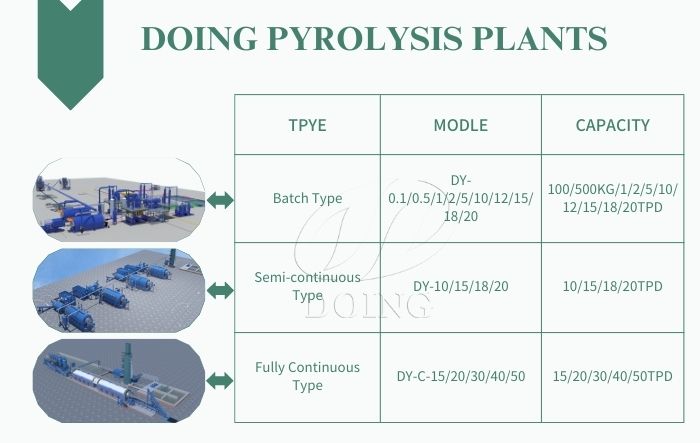

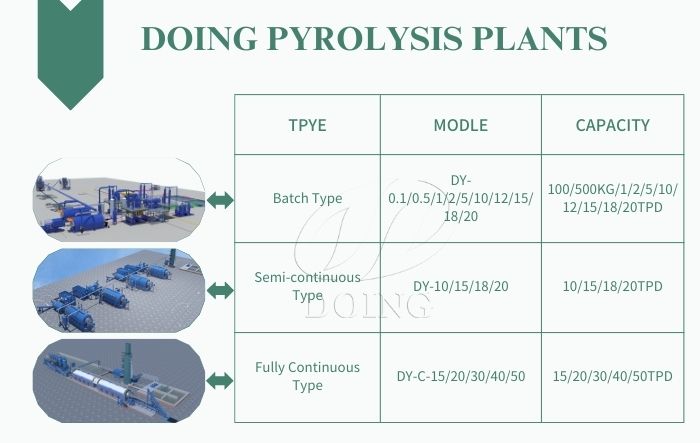

Over the past 13 years, our engineering team has been committed to updating our pyrolysis technology and has researched three types of waste plastic pyrolysis machines:

Type one: Batch type waste plastic pyrolysis machine

About this type, we not only have the skid-mounted one with the processing capacity of 100KG and 500KG per batch, we also have larger processing capacity between 1TPD and 20TPD. So for some customers who have the initial investment ideas about waste plastic pyrolysis machine project, this type is a cost-effective choice.

Type two: semi-continuous waste plastic pyrolysis machine

About

this type, we have the processing capacity between 1TPD and 20+TPD,

which has higher working efficiency and is a popular choice for many

customers.

Three types of DOING waste plastic pyrolysis machines and their capacities

Type three: fully continuous waste plastic pyrolysis machine

About this type, we have the processing capacity between 15TPD and 50+TPD, which can process more waste plastics with higher working efficiency. In addition, our fully continuous waste plastic pyrolysis machine adopts the automatic PLC control system, which can continuously work for nearly two months with high safety and time and energy saving.

All in all, waste plastic pyrolysis machine is the more applicable way to recycle waste plastics, so if you are interested in our waste plastic pyrolysis machine, please feel free to contact the DOING group.

Inquiry more what are the ways of plastic recycling? which one is more applicable? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd