Company news / DATE:2024/10/24

Celebration! In July, 2024, Egyptian customers took an order for DY-15 Model medical waste pyrolysis unit. This order not only signifies the customer's trust in DOING's quality but also underscores our expanding presence in the Egyptian market.

DOING medical waste pyrolysis equipment

The Egyptian customers are engaged in the medical waste treatment business. They had been using the traditional incineration methods to treat waste medical waste, which often has problems such as low efficiency and serious pollution. Seeking a more sustainable and efficient solution, they turned to medical waste pyrolysis technology. DOING pyrolysis units are exported to more than 100 countries around the world, such as Egypt, South Africa, Nigeria, USA, Italy, Russia, India, Colombia, etc. They learned that there are many Egyptian customers purchased pyrolysis units from DOING and gave good reviews. This positive reputation attracted the attention of the current customer, prompting them to inquire about our products.

Among the medical waste, medical blister packs, pharmaceutical aluminum plastic packaging, disposable medical supplies, such as plastic syringes and plastic infusion bags can be turned into fuel oil, aluminum block and the other value resources through pyrolysis unit. In response to the problems of low efficiency and environmental pollution that Egyptian customers are concerned about, the DY-15 Model medical waste pyrolysis unit solution made by DOING engineers can effectively solve:

① The waste medical pyrolysis unit is equipped with an automatic feeder and a high-quality reactor. On the one hand, the feeding speed is fast through the hydraulic push rod. On the other hand, the equipment as a whole is resistant to high temperature and high pressure, which can achieve a certain sterilization effect. The overall operation of the equipment is stable and has a long service life.

Waste medical pyrolysis unit reactor

② The condensation system is equipped with a four-layer tube-and-tube condenser, which can fully cool the oil and gas generated after the pyrolysis of medical waste, guaranteeing the oil yield and high benefits.

Four-layer condensation system of pyrolysis unit

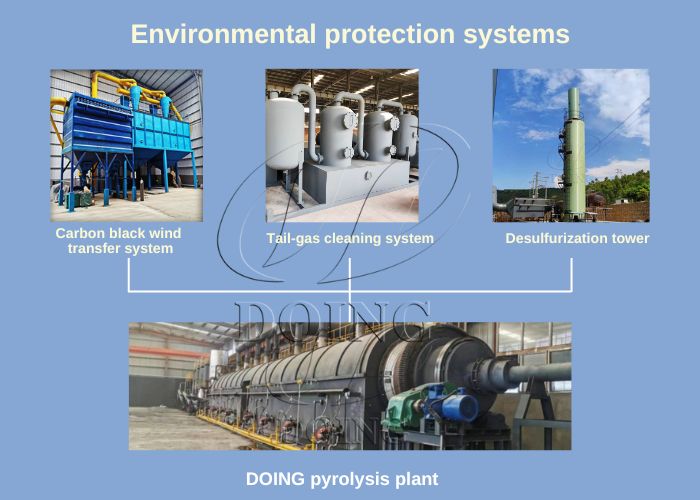

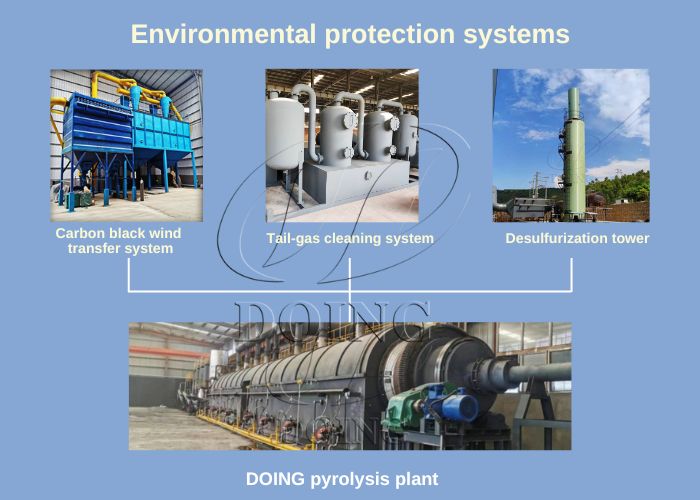

③ The environmental protection device includes waste gas treatment equipment and water circulation system. It is equipped with a dust collector to achieve fully enclosed operation, without dust leakage during the operation, which can effectively solve the air pollution and dust pollution caused by traditional incineration. And it uses circulating water, without waste water generation, ensuring that the entire process is not only efficient but also environmentally friendly.

The environmental protection device of pyrolysis unit

For the subsequent installation, training, and ongoing maintenance services, we DOING will provide comprehensive support to ensure the smooth operation of the DY-15 Model medical waste pyrolysis unit. Please continue to pay attention to us if you are interested.

Inquiry more egyptian customer ordered for dy-15 model medical waste pyrolysis unit information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd