Industry news / DATE:2023/10/19

In recent years, the innovative pyrolysis technology of converting plastic into fuel has become a good solution to plastic pollution and plastic recycling. So, what is the pyrolysis process of converting plastic into fuel? This article will continue to be explored.

1. Collection:

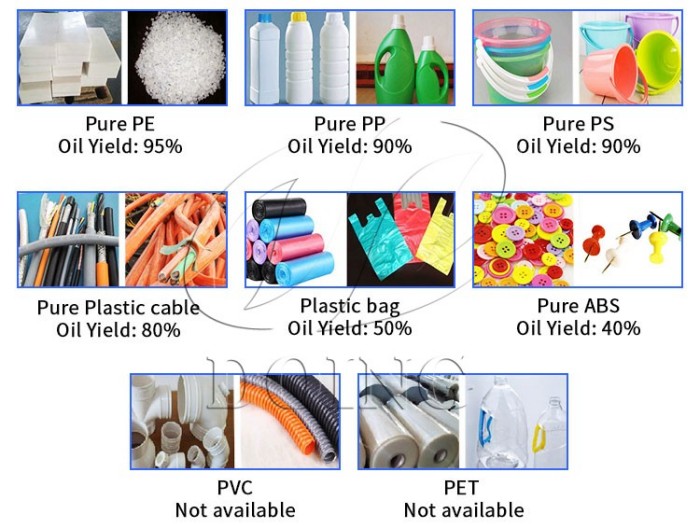

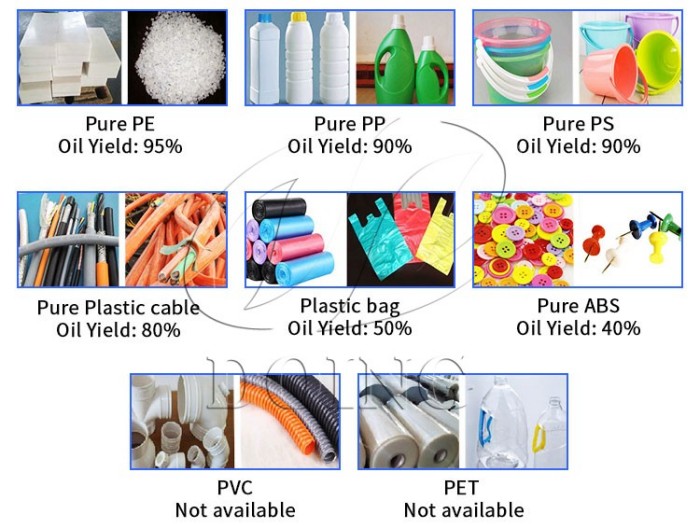

The first step in converting plastic to fuel is the collection of plastic waste. Various sources, including residential, commercial, and industrial settings, are targeted for plastic waste collection. That is, plastics such as pure PP/PE/PS/ABS plastics, pure white plastic sheets, food packing bags, papar-mill waste, plastic household waste and aluminum plastic medical waste should be the main collection objects.

The oil yield of different types plastic

2. Shredding: (Not necessary)

If you want highly efficient and continuous pyrolysis, you can take this step. In other words, DOING continuous plastic to oil pyrolysis machine needs to perform this step, but batch type does not. The plastics go through a shredding process to reduce them into smaller pieces, which is easy to feed and increases efficiency.

3. Pyrolysis:

Pyrolysis involves heating the plastic waste in the absence of oxygen. Waste plastics are mainly long molecular chains. In the process of high temperature heating, long molecular chains are broken into short molecular chains which are the oil-gas and carbon black.

DOING plastic to oil pyrolysis reactor

DOING plastic to fuel pyrolysis reactor adopts automatic and advanced automatic welding technology, which can ensure a perfect sealed space in the reactor, fully pyrolyze plastics and ensure a high oil yield.

4. Condensation:

The oil-gas will be cooled down to the liquid oil and non-condensable gas at the condensers system. This oil is the pyrolysis oil, which is a kind of heavy oil and can be used as a fuel for industrial plants. And the non-condensable gas phase consists of hydrocarbon compounds, including methane flammable gas, which can be used as pyrolysis fuel or for other heating purposes.

5. Distillation:

The fuel oil also can be deep processed by the distillation plants, then it can be refined into diesel fuel. This diesel fuel can be used for power generation or agricultural diesel engines.

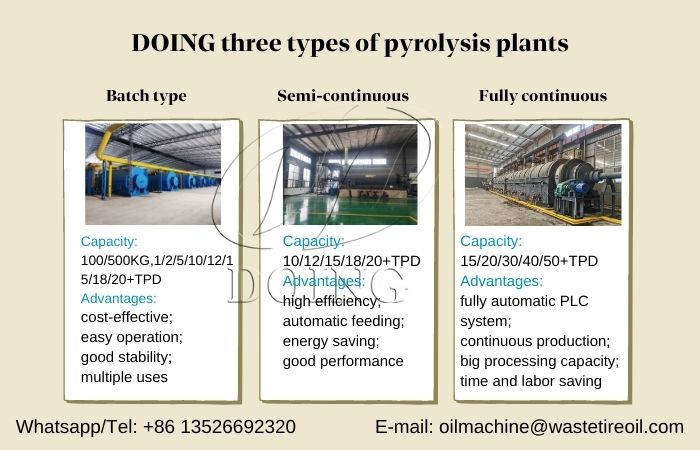

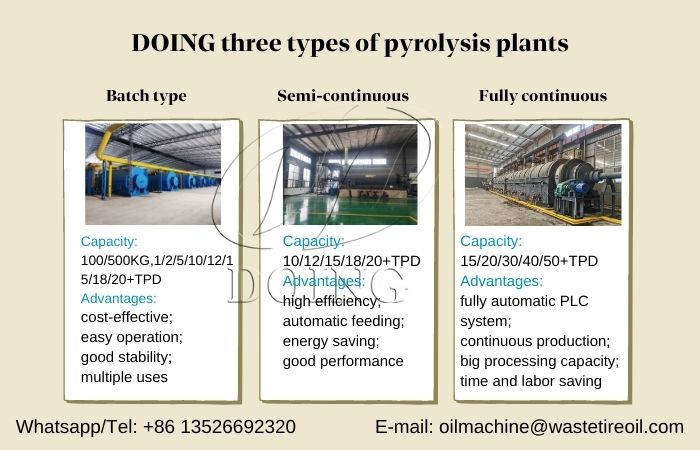

The above is the plastic to fuel pyrolysis process of DOING waste plastic to fuel pyrolysis machine. DOING supplies different processing capacities of pyrolysis machines, which can meet different customers' needs. Also, our plastic to fuel pyrolysis machines are equipped with environmental protection devices. It has no air, water and dust pollution.

The different types of DOING plastic to oil pyrolysis machines

If you're interested in our waste plastic to fuel pyrolysis machines, welcome leave us a message. We have professional sales and the engineers team can provide the best plastic project report for you.

Inquiry more what is the process of converting plastic to fuel? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd