Industry news / DATE:2024/6/27

With the increasing amount of plastic waste in our daily life, how to properly and non-pollutingly handle these plastics and turn them into treasures has become a direction of exploration for many people. And due to the unique components of plastic waste, reverting plastic scrap to oil with the scrap plastic pyrolysis machine becomes one popular and profitable choice.

DOING scrap plastic pyrolysis machine for sale

Generally, in addition to oil, during the pyrolysis process, we can also obtain the carbon black and combustible gas, which have wide applications to help our customers generate more profits.

Then let me have a brief introduction about the main systems and the recycling process of the scrap plastic pyrolysis machine:

1. Pyrolysis Reactor: we need to feed plastics into the reactor, which is heated to a certain high temperature, usually between 300°C to 600°C. In the absence of oxygen, the plastic undergoes thermal decomposition, breaking down into a gaseous mixture, that is, oil gas;

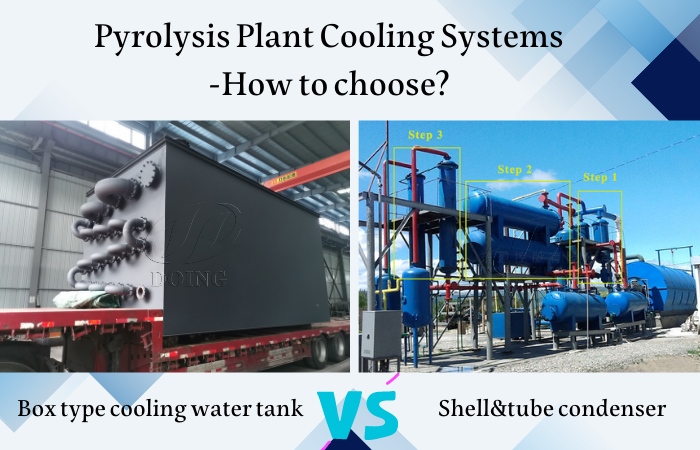

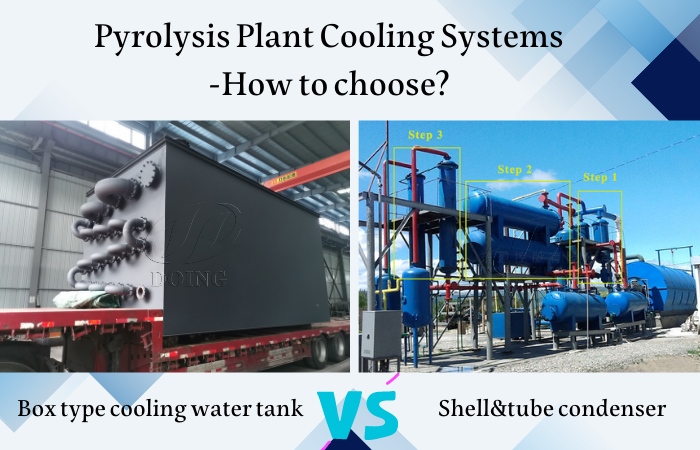

2. Cooling system: The oil gas produced is cooled down into liquid oil after going through the cooling system. DOING condensers type cooling system adopts 3 steps of cooling system to ensure that there is enough cooling area to cool the all of oil gas. In addition to this type, DOING also has the other type: water tank cooling system, which is easy to transport and install, and it also has a good cooling system. Our customer can choose the suitable one based on their situation.

Two types of DOING cooling system for pyrolysis machine

3. Oil collection system: The resulting liquid oil, often referred to as plastic pyrolysis oil or fuel oil, can be used in cement plants, steel plants, glass plants and other heavy oil plants and can also be further refined to non-standard diesel to be used as a fuel source for industrial boilers, generators, or ships and trucks. For the 3 steps cooling system, we match 3 oil storage tanks under them. Different quality oil can be collected in different oil tanks to improve customer's profit. This is also the important difference between that old design machine in the market.

DOING exhaust gas purification system

4. Exhaust gas purification system: after the oil gas cooled into fuel oil, the remaining exhaust gas will go through the exhaust gas purification system(tail gas cleaning system and desulfurization tower) to make further purification to meet the emission standards in various countries.

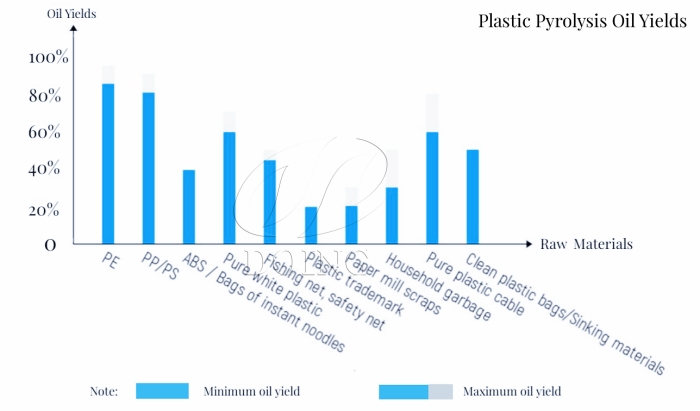

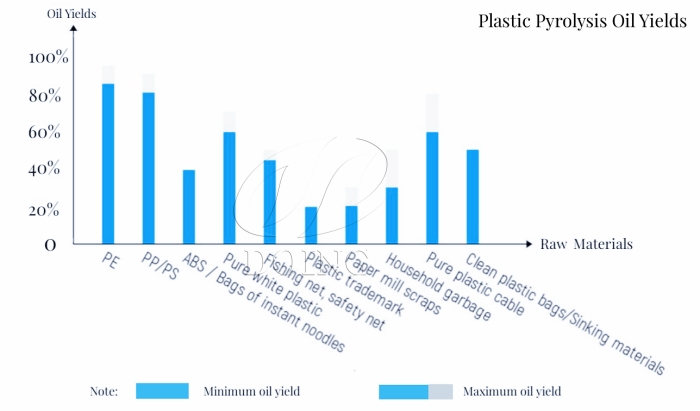

Commonly, the quality and quantity of the obtained fuel oil from scrap plastic varies from the type and purity of the scrap plastics. The following are the oil yields of the different plastics:

Oil yields of different plastics

In addition to learning about the scrap plastic pyrolysis machine, if you want to enter the plastic pyrolysis industry, you also need to consider other factors, such as raw materials, processing capacity, factory planning area, etc. DOING, as an experienced manufacturer and supplier of plastic pyrolysis machine, if you have any questions about the plastic pyrolysis machine project, just feel free to contact us, we are waiting for your messages.

Inquiry more what machine reverts scrap plastic back to oil? information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd