First of all, we must know how to obtain tire pyrolysis oil. After knowing the source of tire pyrolysis oil, we can determine whether tire pyrolysis oil is friendly to the environment. Tire pyrolysis oil is obtained by treating waste tires in a pyrolysis plant. But why can we get pyrolysis oil from pyrolysis of tires? Because the main component of tires is rubber, which makes up about 50% of the tire composition, made from small olefin molecules in petroleum and polymerized under high pressure.

If the rubber is to be turned back into oil again, the reverse process of polymerization of rubber must be carried out in order to convert the large molecules in the rubber into small molecules and reduce them to petroleum groups.Therefore, tires contain petroleum components that can be pyrolyzed out by pyrolysis plant, which is called tire pyrolysis oil.

Tire pyrolysis oil obtained from pyrolysis plant

Tire pyrolysis oil obtained from pyrolysis plant

In fact, tire pyrolysis oil itself is petroleum, but it is extracted from waste. Some components will be changed, but not their calorific value, i.e. more than 10,000. calories, which can be used in some heavy industrial plants, such as boiler plants, cement plants, steel plants, brick plants, glass plants, heavy oil power plants, heating centers, etc.

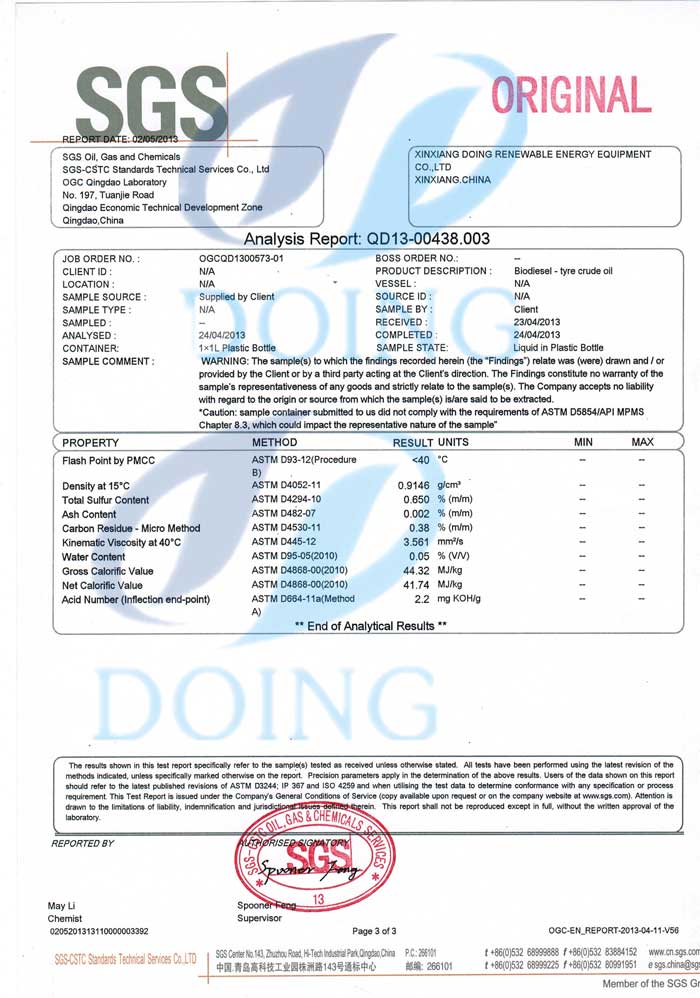

If you find some heavy industry factories want to buy this tire pyrolysis oil, and they are worried whether the tire pyrolysis oil is friendly to the environment, you can send our SGS report of tire pyrolysis oil to them to see if it meets their standards.

SGS report of tire pyrolysis oil

SGS report of tire pyrolysis oil

Actually, tire pyrolysis oil is environmentally friendly and it is similar to heavy oil used in industrial factories. Generally, heavy industrial plants are equipped with desulfurization and dust removal devices, so the flue gas produced by burning tire pyrolysis oil can meet environmental emission standards. If you want to know more pyrolysis oil cases, please contact us freely.