Waste tires are mainly composed of rubber, carbon and other organic components. After pyrolysis, waste tires are pyrolyzed into oil gas and solid residue, which includes carbon black and steel wires. The oil gas can be liquefied into liquid fuel oil, which is the main product of waste tire pyrolysis plant; the carbon black and steel wires can be discharged after the process is finished. Do you want a high oil yield to improve your revenue? Temperature control is one of the most important factors for fuel oil output, and a good temperature control can guarantee the high oil yield and safety.

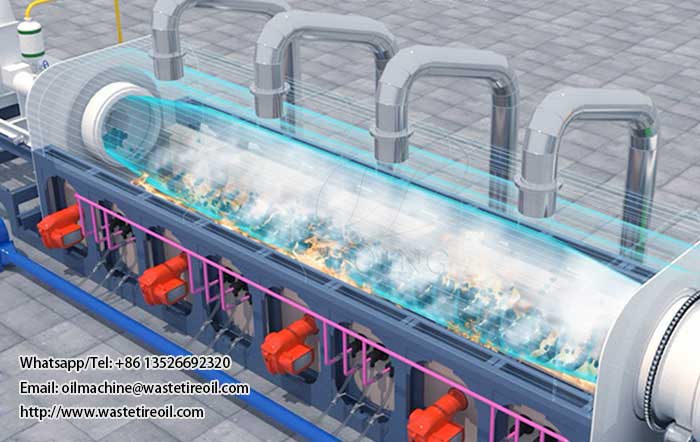

Waste tires heated in pyrolysis reactor

Waste tires heated in pyrolysis reactor

So what is the temperature range required for tire pyrolysis? Generally speaking, the decomposition of waste tires begins at about 290℃ and ends at about 570℃, and the oil yeild is the highest at 300℃. If the temperature is too low, the waste tires can't get sufficient pyrolysis, then the oil output will be reduced. If the temperature is too high, the content of non-condensable gas will be generated more, so the fuel oil output cannot be higher.

Doing waste tire pyrolysis plant is equipped with digital thermometers to help the corresponding pyrolysis temperature control for our customers. In our waste tire pyrolysis plant installation & operation manual, we clearly state the pyrolysis temperature for different pyrolysis stages so that our pyrolysis plant users can control the temperature well and get a good oil yield.

Waste tire pyrolysis plant installation & operation manual

Waste tire pyrolysis plant installation & operation manual

Besides waste tires, Doing waste tire pyrolysis plant can also process other kinds of rubber and various plastics. The pyrolysis temperature will be a little different for different raw materials. For more details, please feel free to ask us by sending inquiries.