Oily sludge is a hazardous waste containing emulsified petroleum hydrocarbons, water, heavy metals, and solid particles which will cause serious environmental problems without proper disposal. Thus to find a proper way to dispose of the oily sludge is a significant concern now.

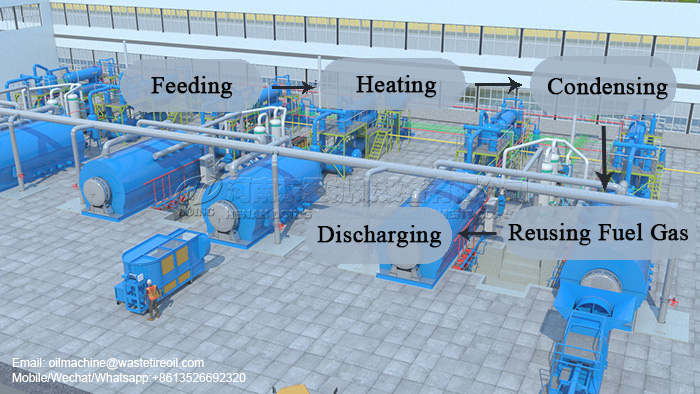

The working process of waste oil sludge pyrolysis plant

We Doing Group according to the characteristics of oily sludge has produce the waste oil sludge pyrolysis plant to convert the harmful oily sludge into useful fuel oil, clean soil and water. Now let’s see how the waste oil sludge pyrolysis plant works to dispose of the oily sludge.

1.Feeding the oily sludge into the pyrolysis reactor through a screw feeder (If your oily sludge is liquid, it needs to be packed in ton bags firstly, while solid oily sludge can be fed directly)

2. Heating pyrolysis reactor, then waste oil sludge rotation evenly heated in the reactor. Then it will be pyrolyzed into oil gas with the temperature rising.

3. Condensing the oil gas into liquid oil and collect them into the oil tank.

4.Recycling the incondensable gas to heat the pyrolysis reactor after it passes the gas purification system. At the same time, ash and harmful gas will be cleaned.

5.Discharging the other residues (clean soil) by the auto screw discharger.

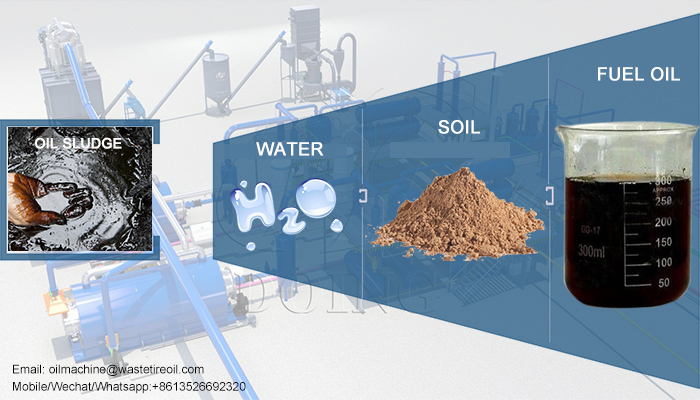

The final products of waste oil sludge pyrolysis plant

After the above process, you can get fuel oil,water and clean soil from oily sludge. Choosing Doing waste oil sludge pyrolysis plant, the quality of waste oil sludge pyrolysis plant is absolutely guaranteed.

The main advantages of waste oil sludge pyrolysis plant:

1. Safety

The waste oil sludge pyrolysis plant has equipped with many mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, which will guarantee 100% safety in the waste oil sludge pyrolysis plant working process.

Safety devices of waste oil sludge pyrolysis plant

2. Energy-saving

The incondensable gas can be recycled to heat the pyrolysis reactor which will reduce additional fuel consumption. And DOING waste oil sludge pyrolysis plant adopts external rotation of reactor, the body of which can be rotated 360 degrees, so that the raw materials can be heated equably suing the limit heating fuel.

2.Environment friendly

In the dedusting system, three steps (water spray, ceramic ring filter, washing chamber) are used to dedust the extra gas and more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged into the air directly.

Tail gas cleaning system of waste oil sludge pyrolysis plant

If you have a lot of oily sludge to dispose, welcome to contact with us, we Doing Group can offer you the waste oil sludge pyrolysis plant with high quality and low price.