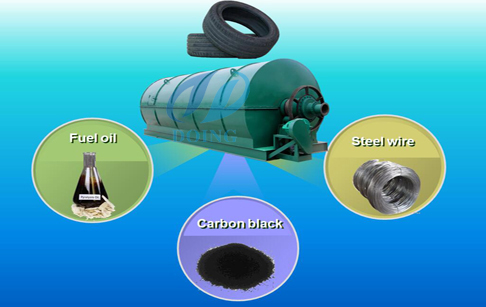

Waste tyre pyrolysis plant

The DoingGroup's waste tire cracking equipment is a process that uses pyrolysis chemical reactions to crack waste tires into fuel, carbon black, steel wire, and flammable gases. It is undeniable that most people now evaluate a set of pyrolysis equipment as a first rate factor. Of course, this is also our primary guarantee. But what else do you have to protect your waste tire pyrolysis plant?

DoingGroup designs a waste tire pyrolysis plant in a highly responsible attitude towards its customers. Not only consider the output of the equipment, but also take into account the personal safety of each customer.

The specific safety device mainly includes the following aspects:

DoingGroup's waste tyre pyrolysis plant safety device

The reactor adopts a unique three-step welding process. This welding process is not easy to crack and is sufficient to ensure safety.

2. The oil-water separator can purify oil and gas and prevent oil and gas from flowing back.

3. The water seal can purify the exhaust gas and prevent the backward flow of exhaust gas.

4. Vacuum device, can drain oil and gas, and can maintain pressure balance in the furnace.

5. The recoil tank can buffer the oil flow escaping from the reactor and slow down the oil and gas velocity, thus ensuring that the entire equipment is operated under a safe pressure environment.

DoingGroup's tyre pyrolysis plant

Did you know that the waste tire pyrolysis plant has such comprehensive safety settings? Even a welding seam must be done to the extreme. This is our pursuit of quality, and it is our consideration of the safety of each customer. This kind of equipment is the best choice for your investment!