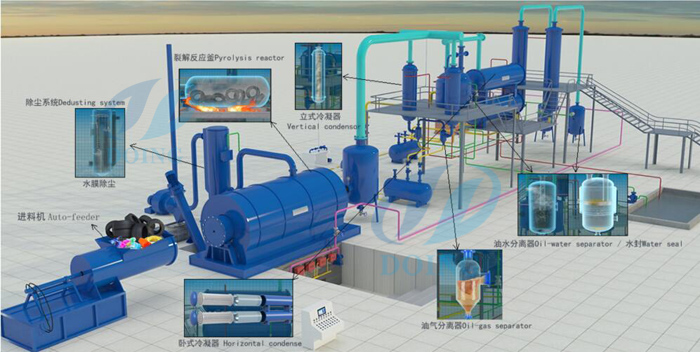

Conversion of plastic waste to fuel oil machine

The pyrolysis process for plastic takes the long chain polymer molecules and breaks or cracks them into shorter chains through heat and pressure. Essent ially the process is same the natural process of the earth to break down carbon into oil which takes million of years in nature. The pyrolysis process does this with intense heat in a closed system in a short amount of time. Conditions for producing pyrolysis oil are more likely to include virtually no oxygen. The pyrolysis of plastics produces a liquid product, pyrolysis oil or oil that can be readily stored and transported. Conversion of plastic waste to fuel oil is the thermal de-polymerization process in the absence of oxygen which is able to convert plastic into gasoline-range hydrocarbons

Conversion of plastic waste to fuel oil working process

The waste plastic used in pyrolysis process is needed to be sorted and cleaned. The Polyethylene (PE) and Polypropylene (PP) which are the main component of the plastic in municipal solid waste are used in the process in order to prevent the contamination of chlorine in the oil

The classified waste plastic is processed from an autoclave pyrolysis reactor. In general, product yields from pyrolysis are varied with temperature. The plastic pyrolysis oil used in this research is processed at 300-500 °C t atmospheric pressure for 3 hours. The product output consists of 60-80% pyrolysis oil, 5-10% residue and the rest is pyrolysis gas on weight basis。