Tyre oil to diesel recycling plant

Tyre pyrolysis oil can be refined into valuable diesel oil through catalytic cracking and high temperature distillation technology. It is a method of separating mixtures based on differences in volatilities of components in a boiling liquid mixture. After beling distilled by the distillation plant, the oil may have dark color with bad smell, then we suggest to deep purify the oil, with matched color and smell removal system, you will get clean diesel oil as final products with beautiful light yellow color.

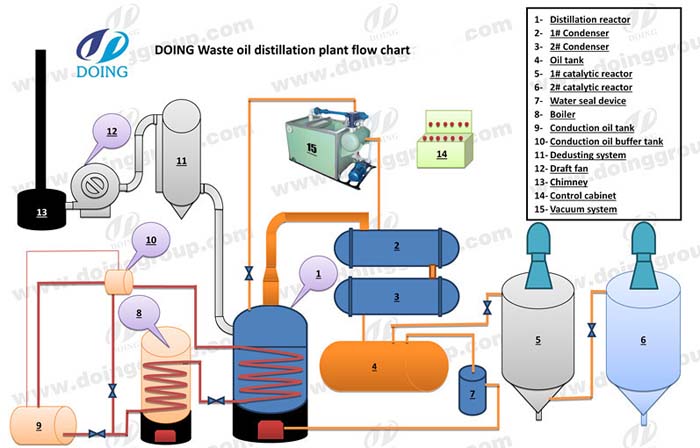

Tyre oil to diesel recycling plant working process

Tyre oil to diesel recycling plant working process

1. Prepare waste oil(waste plastic oil ,waste tyre oil ,used motor oil ,used engine oil )

2. Heating for distillation

3. Cooling

4. Chemical process for cleaning the distillation oil

5. Collect final diesel product

Tyre oil to diesel recycling plant final product

Diesel Oil (85%-90%)

Diesel fuel application

Apply to tractors, trucks, ships, diesel oil generators, power generators, etc.

Slag (5%)

Recycle it into furnace to heat reactor.

Sysnas (5%)

Recycle it to heat the distillation system, storage the gas for heating, liquefied.