The pyrolysis plant is to convert the waste plastic to oil for fuel, for different kinds of waste plastics, the oil yield is also different. The oil yield differs ranges from 95% to 30%.

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

| Leftovers of paper | Wet:15%-20% dry:60% |

| House garbage | 35%-50% |

| Plastic cable | 80% |

| Plastic bag | 50% |

| Submarine cable | 75% |

| Rubber cable | 35% |

| sole | 30% |

| Big tires | 40%-50% |

| Small tires | 35%-40% |

| PVC | Not suitable |

| PET | Not suitable |

| PE CABLE SKIN | ≈85% |

| PVC CABLE SKIN | ≈25% |

| Pure rubber cable skin | ≈35% |

| Telephone wire | ≈50% |

| Weaves &Handbags | ≈60% |

| Common rubber pipe | ≈30% |

| Carpets | ≈35% |

| Aluminum foil | ≈30% |

| Car glass bead | ≈50% |

| PP beverage bottle | ≈50% |

| shoes | depends on plastic composition |

| Sport shoes’ sole | ≈27%-33% |

| Black rubber | ≈35% |

| Gum outsole | ≈45% |

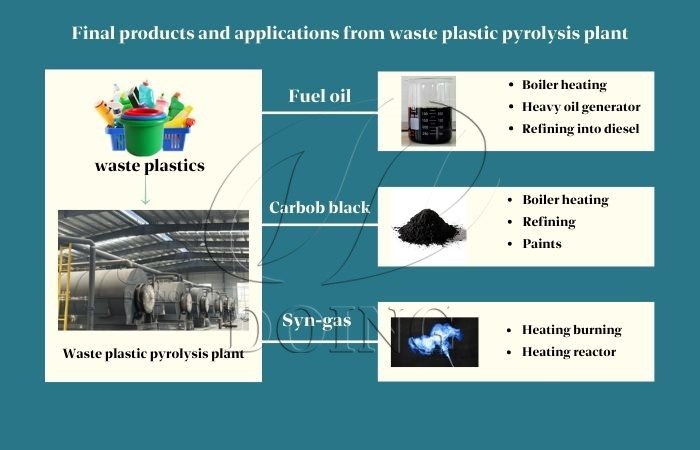

The final products of waste plastic pyrolysis are fuel oil, carbon black, and oil gas.

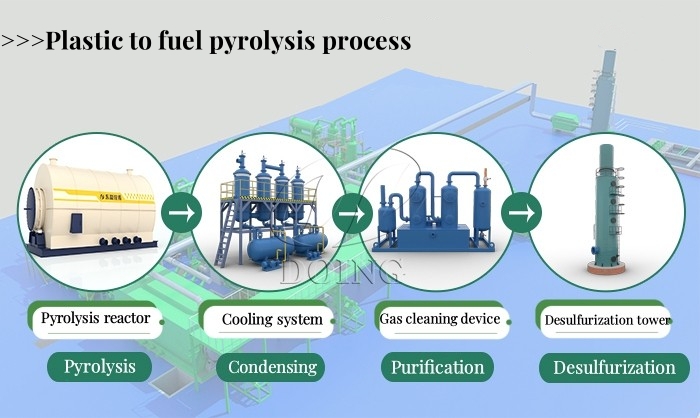

1. How does pyrolysis plant convert waste plastic into oil?

Plastics are made of polymer compounds, usually composed of polymers and additives. Different types of waste plastics have different chemical structures and thermal stabilities, which have an important impact on their pyrolysis potential and oil yield. In addition to the PVC (polyvinyl chloride) and PET (polyethylene terephthalate), most waste plastics can be converted into fuel oil by pyrolysis plant through thermal decomposition processes.

Thermal decomposition is a process in which polymers are heated to high temperatures and decomposed into low molecular compounds in an oxygen-deficient or low-oxygen atmosphere. During this process, waste plastics are decomposed into liquid and gaseous products by pyrolysis plant.

Waste plastic to oil pyrolysis process

2. What factor will influence the oil yield of waste plastic?

The oil pyrolysis yield of waste plastics ranges from 30% to 95%, depending on several factors. First of all, the type of plastic has an important impact on the oil yield. Some plastics, such as polyethylene (PE) and polypropylene (PP), have higher oil yields because they break down relatively easily at high temperatures. Some other plastics, such as polystyrene (PS) and polycarbonate (PC), may have lower oil yields due to their more complex structures.

Secondly, the impurity content in waste plastics will also affect the oil yield. Impurities, such as pigments, additives and contaminants, may reduce the pyrolysis potential of waste plastics and reduce oil yield. Therefore, you can choose to pre-treat and clean waste plastics before undergoing the pyrolysis process.

In addition, the maturity of pyrolysis technology, the specific configuration and operation of pyrolysis plant, will also have an impact on the pyrolysis process and oil yield. For example, DOING pyrolysis plant is equipped with a specially designed negative pressure device, which not only ensures that the oil gas generated by plastic pyrolysis are fully extracted, but also ensures the safety of equipment operation and prevents flash explosions. For equipment operation of workers, we Henan Doing Company also provide one-stop technical training.

Plastic pyrolysis plant manufacturer services of DOING Company

3. What are the applications of waste plastic pyrolysis into oil products?

Plastic oil obtained from waste plastics pyrolysis plant can be used as fuel in large cement plants, brick making factories, glass plants, steel plants, etc., for heating uses; for further applications, it’s suggested to use waste oil distillation plants to refine plastic pyrolysis oil into non-standard diesel, which can be used in trucks, tractors, heavy machinery, diesel generator sets, ships, boats, etc. While another product, carbon black, can be further processed and finely ground into powder for use in the tire rubber manufacturing industry. The oil gas, also called syn-gas, can be used to heat the reactor of waste plastic pyrolysis plant to save investment cost. In the process of pyrolysis waste plastics into oil, basically 100% utilization of waste plastics is a good way to alleviate environmental pollution from plastic waste.

Final products applications of waste plastic pyrolysis plant

In short, there are differences in the oil yield rates of various waste plastics during the pyrolysis process. Pure PE, PP and PS have high oil yield, while PVC and PET are not suitable for pyrolysis. These oil yield data provide an important reference for the application of waste plastic pyrolysis technology, helping to optimize the recycling and environmental protection of waste plastic resources. If you want to know more about waste plastic to oil pyrolysis plants and project construction guidance, please contact China-Doing Company.