Pyrolysis plastic to diesel fuel machine product introduction

Pyrolysis plastic to diesel fuel machine

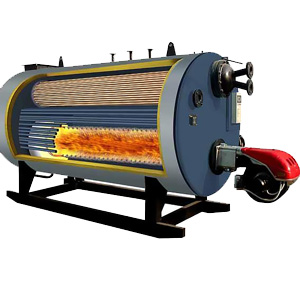

Pyrolysis plastic to diesel fuel machine adopts one advanced technology called refining or distillation, which takes advantage of high temperature and heat the plastic oil to working temperature by using fuel oil, gas, coal etc. as fuel materials.

Through changing forms of the oil from liquid state to gaseous state and then from gaseous state to liquid state, the distillation technology can successfully remove the particles, colloidal matter, acid and odour from plastic oil by acid- treatment and filtration.

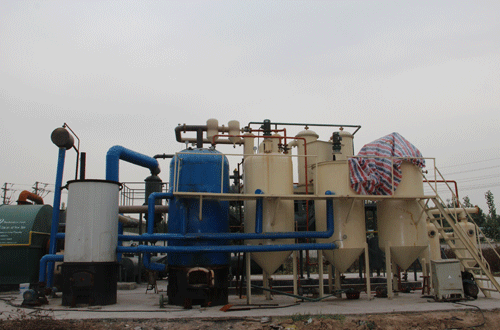

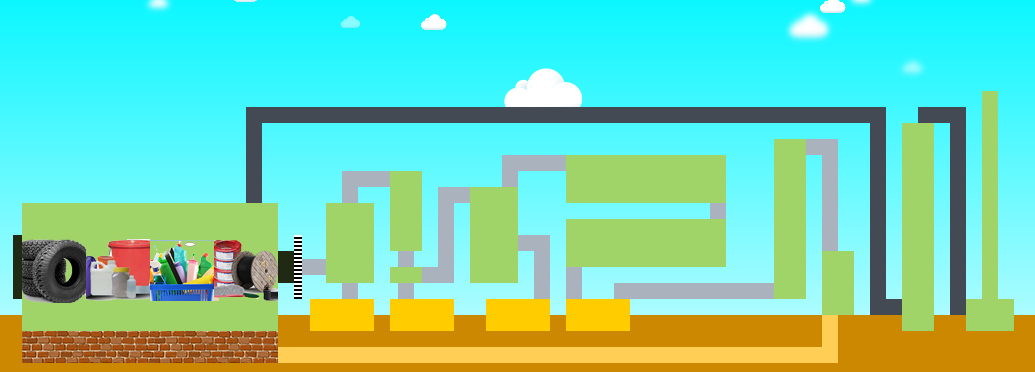

Pyrolysis plastic to diesel fuel machine working process

Pyrolysis plastic to diesel fuel working processs

1. Pump waste plastic oil into distillation reactor by oil pump.

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

Pyrolysis plastic to diesel fuel machine final product

Diesel fuel

Finally we get qualified diesel fuel with clean and transparent color and qualified smell. Having high economic values, these diesel oil can be widely used in low speed engine and generators such as digging machine, road roller, loading machine and so on.

| Technical parameter of pyrolysis plastic to diesel fuel machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tyre, waste plastic, waste rubber, |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd