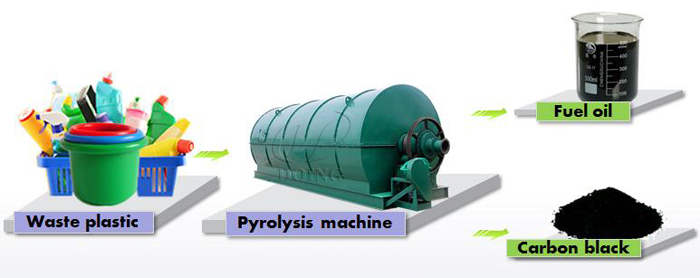

Recycling of waste plastic to oil machine product introduction

Plastic to oil

As the application of the plastic products becomes wider and wider, the pollution caused by plastic waste is also a huge problem. Some of the developed countries have put many emphasis on developing the recycling of waste plastic to oil machine.

Recycling of waste plastic to oil machine

The pyrolysis technology is a new invention, and the recycling of waste plastic to oil machine can turn the plastic waste into fuel oil, carbon black and combustible gas.

The plastic pyrolysis process is harmless to the environment and operator, in addition, when you first use the plant, we will assign you the professional technician, who can help you in installing and running the plant. So you can operate the plant easily.

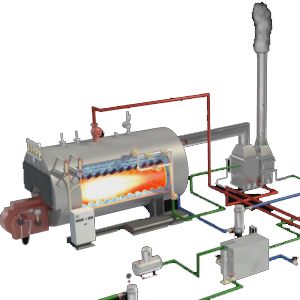

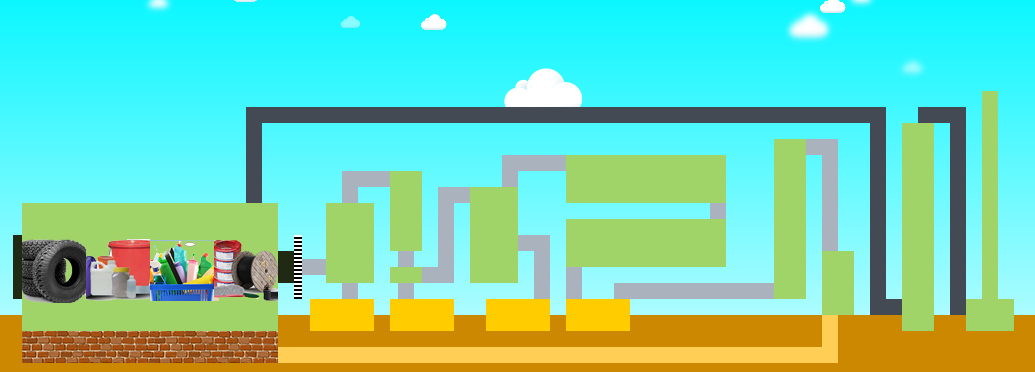

Recycling of waste plastic to oil machine working process

Recycling of waste plastic to oil machine working process

1. Put dried plastic waste into reactor and the quantity shall be controlled under 2/3 of reactor for rotating more smoothly. Then close the feeding door.

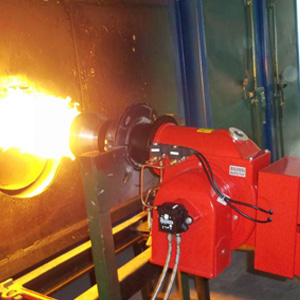

2. The plastic to fuel oil conversion includes two stages. From 100℃ to 250 ℃ is the preliminary stage. The light oil gas shall be released at 100 ℃ and fluid oil shall be released at 120℃ . From 280℃ to 350℃is the top output rate interval. Oil gas will be collected into manifold, heavy particles and oil will be gathered and liquefied in center of manifold and drop down into the heavy oil tank. The lighter gas will rise up to the multi-functional oil condensers, then be liquefied into oil and stored in the oil tank. The incondensable gas through de-sulfuration and de-dusting by hydroseal will be led to heat the furnace for reducing the energy cost.

3. Cool down the plastic pyrolysis reactor after the process. Carbon black will be discharged automatically when the temperature falls down to 50-70 degrees.

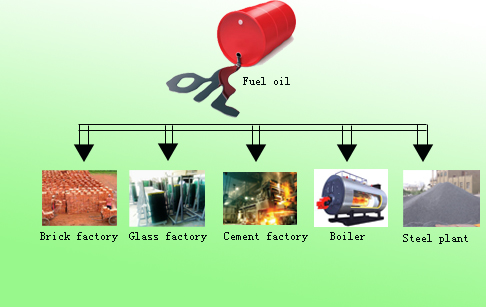

Pyrolysis oil (plastic oil) application

Pyrolysis oil application

1. Add it into heavy oil generator to produce electricity.

2. Used as heating material.

3. Sell it into oil refining factory to further process it. Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc.

Carbon Black Powder (30% to 35%)

Carbon black application

The second product recycling of plastic to oil machine is carbon black. The quantity of carbon black is about 30% to 35% according to plasticquality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compare to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

| Technical parameter of recycling of waste plastic to oil machine | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

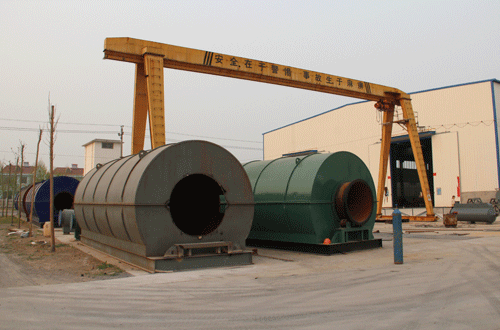

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

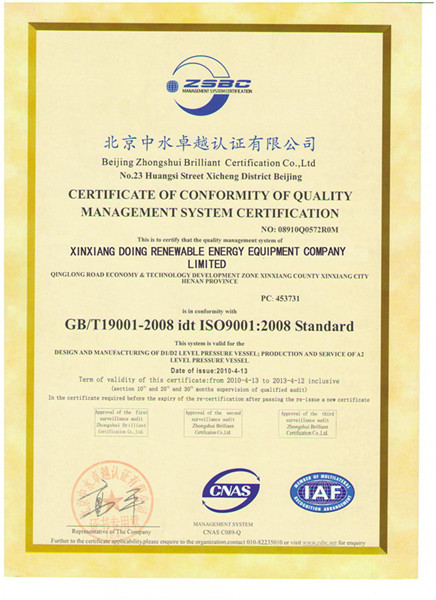

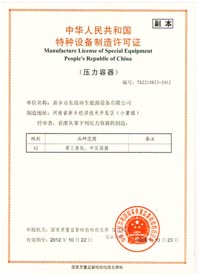

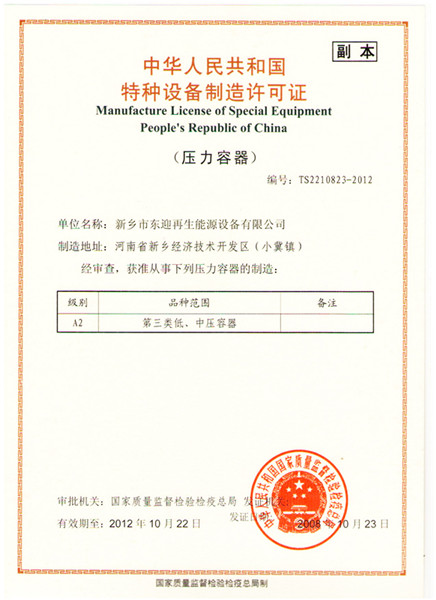

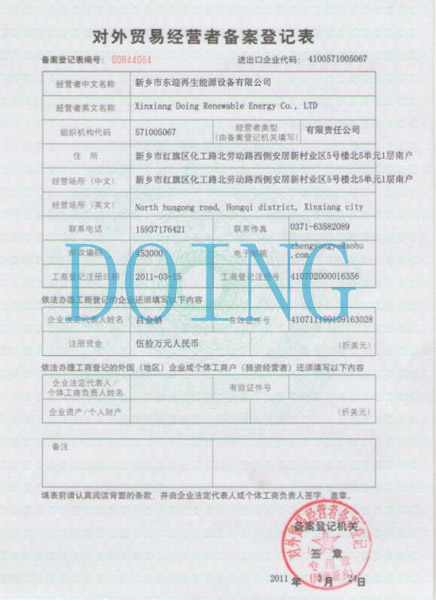

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd