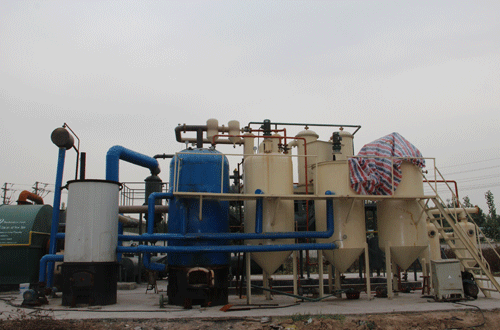

Plastic to diesel process distillation plant product introduction

Waste plastic to diesel process distillation plant

As the speed development of plastic industries, the application of plastic products has been becoming wider and wider. The wide application of the plastic products bring many convenience to people’s life, but in the same time, it causes problems. As we all know that plastics are very difficult to decompose in the natural environment, thus more and more plastic waste generate serious environment pollution.

Plastic to diesel process distillation plant

Through 2 year research and study, we developed a new technology to combine the pyrolysis and distillation in the same process, also with fractionation. The machine name is plastic to diesel process distillation plant .Through tPlastic to diesel process distillation plant, you could get diesel, gasoline and heavy oil separately in the same time.

Plastic to diesel process distillation plant raw material

PET (Polyethylene Terephthalate).

Examples: Soft drinks bottles, food grade packaging and trays.

PVC (Polyvinyl Chloride). Examples: Pipes, window fittings, bottle s and laminates.

Other Examples: Foams, nylons and fiberglass

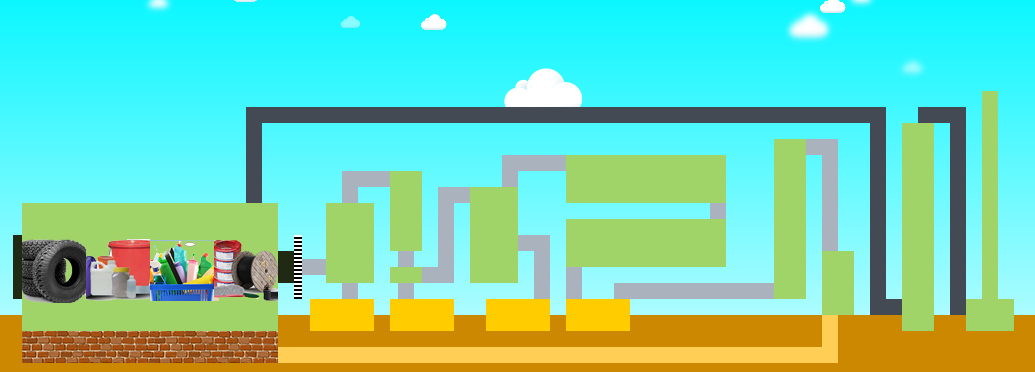

Plastic to diesel process distillation plant main process

Plastic to diesel process distillation plant process plastic to diesel

1) Feeding

It needs the input materials shredded or crushed into small pieces less than 3-5cm for automatic and continuous feeding;

2) Preheating to remove Dioxin

As we all know that Dioxin is very easy to be produced from many kinds of waste burning process, especially chlorine substance, like PVC plastics, paper-mill waste, household garbage, etc. And the emission of Dioxin will cause serious problems to the environment and human body, thus it need to be seriously disposed and removed before released to the air.

3) Pyrolysis

After remove the Dioxin, the input materials will go to the pyrolysis reactor for further heating and cracked to oil gas.

4) Catalysis

5) Distillation

6) Fractionation

7) Extra gas recycling and collection

8) Carbon black slagging

Plastic to diesel process distillation plant final product

Plastic to diesel process distillation plant final product

1) Diesel

2) Gasoline

3) Heavy oil

4) Carbon black

| Technical parameter of plastic to diesel process distillation plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste engine oil, plastic oil, tyre oil, |

| Structure form | Vertical (easy cleaning and maintenance) |

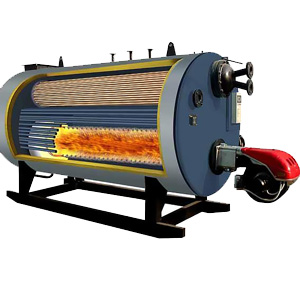

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd