Waste tyre to fuel oil recycling pyrolysis plant product introduction

Waste tyre to fuel oil recycling pyrolysis plant

Waste tyre to fuel oil recycling pyrolysis plant

Waste tyre pyrolysis is a thermo decomposition of tyre polymer, since waste tyres are long chain polymers containing more than 50,000 carbon atoms attached to each other in a cross linked or straight chain.

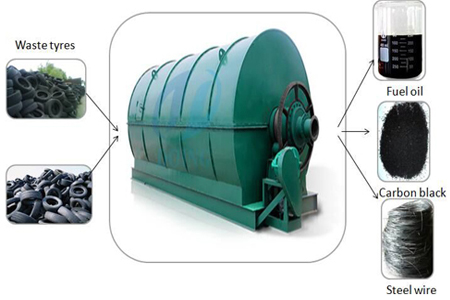

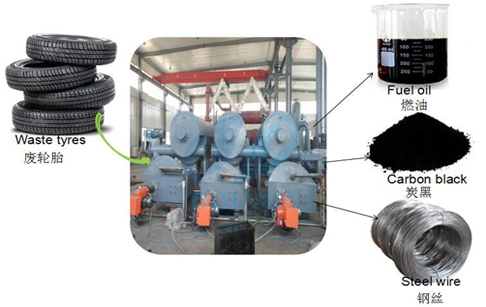

For waste tyre to fuel oil recycling pyrolysis plant, its raw material can be waste tyres, plastic and other rubber. If your raw material is waste tyre, you can get fuel oil, carbon black and steel wire after pyrolysis processing. The following are the function of products from waste tyre to fuel oil recycling pyrolysis plant .

Waste tyre to fuel oil recycling pyrolysis plant raw material

The raw material of Waste tyre to fuel oil recycling pyrolysis plant

Waste tyre

Waste plastic

Waste rubber

Waste tyre to fuel oil recycling pyrolysis plant final product and application

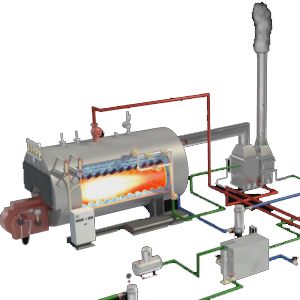

Fuel oil (45%-52%):

The main product-fuel oil produced by ourWaste tyre to fuel oil recycling pyrolysis plant is widely used for industrial and commercial purposes.

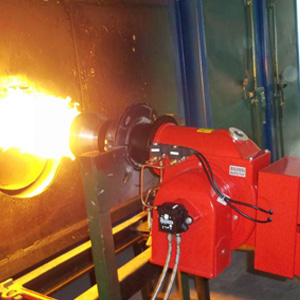

With the heating value 10592.48Kcal/Kg, this fuel oil is a kind of good heating fuel which can be applied for boiler factory, cement factory, boilers, glass factory and steel mill, etc.

Carbon black after s (30%):

Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials.

It is more price-efficient to be used as an ingredient in the industries listed:

1.Cement factory

2.Conveyor band

3.Carrier Bands

4.Hose and doormat

5.Black nylon bag

6.Rubber additive

7.Heat isolation

Steel wire(15%)

Steel wire can be sold to steel factory directly.

| Technical parameter of waste tyre to fuel oil recycling pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

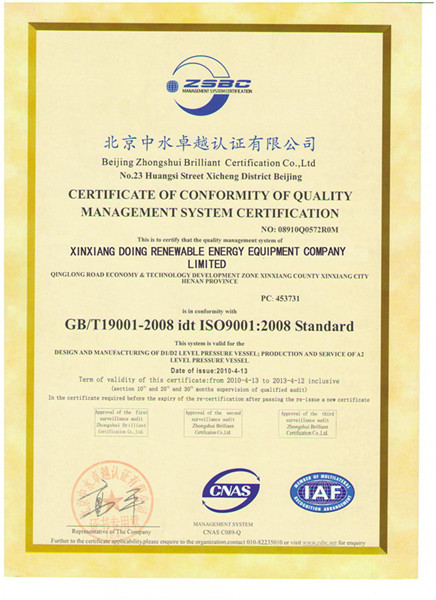

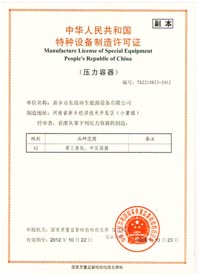

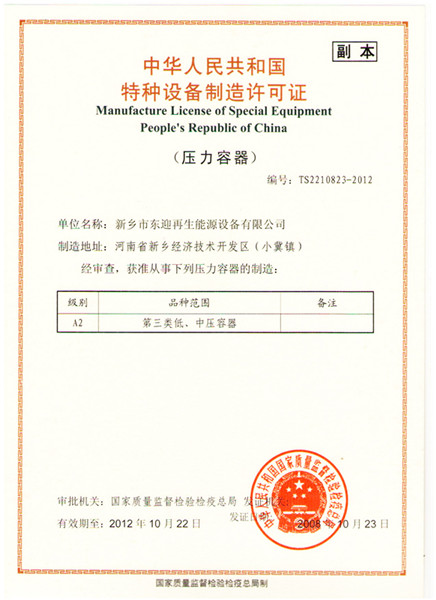

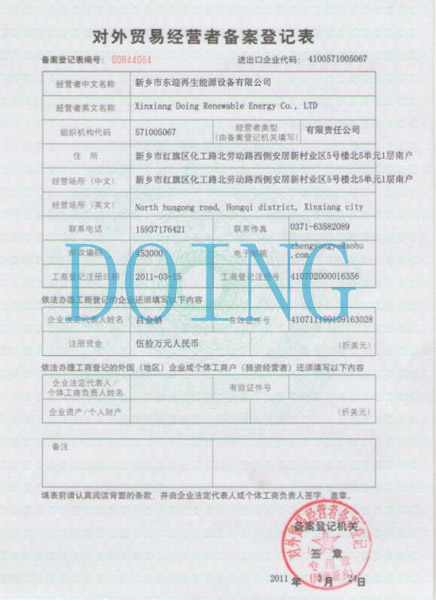

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd