Waste tire pyrolysis plant reactor product introduction

Waste tire pyrolysis plant reactor

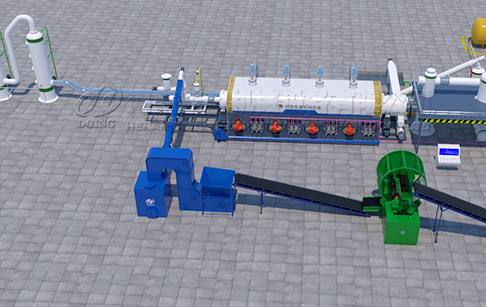

The waste tire pyrolysis plant reactor is made by two different parts,including the reactor and the insulation.

The material of our reactor is can be Q245R,Q345R boiler plate or 304 and 304 stainless.The thickness of the whole reactor plate is 16mm.Our reactor is manufactured exactly according to the standard of pressure vessel.The cap of the reactor is ellipsoidal ,just like a shell。 This design has a stronger tension and can be welded by automatic welder. And compared to the labor welder, automatic welding is more professional and precise.

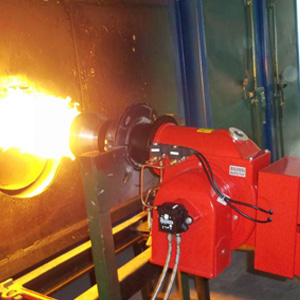

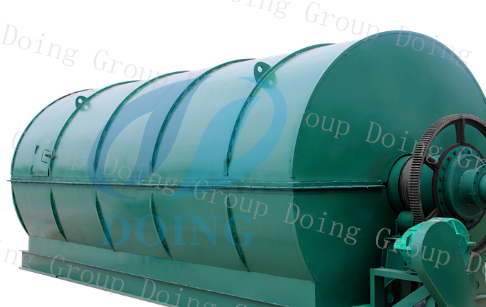

Here is a picture ofwaste tire pyrolysis plant reactor in our factory:

Waste tire pyrolysis plant reactor in our factory

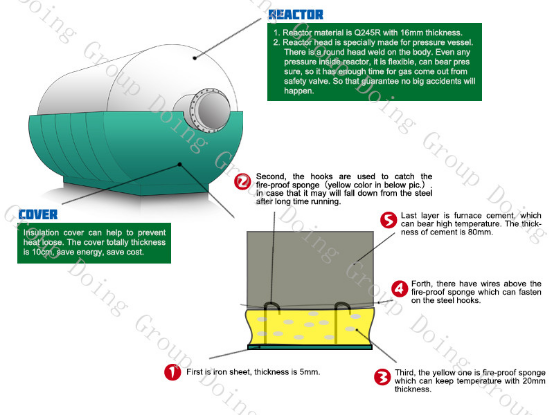

Outside of the reactor, there is an insulation.It can keep the heat inside

And our insulation is made by 5 layers,which is more thick than others.

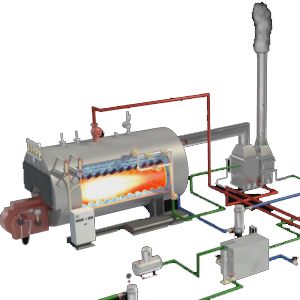

Here is a picture of waste tire pyrolysis plant reactor insulation in our factory:

Waste tire pyrolysis plant reactor insulation in our factory

The reactor will be covered by insulation. Between them, there is a gap.the smoke from furnace will flow from this gas to the dedusting system and after dedusting system, the smoke will be very clean.There is no air pollution.

Pyrolysis plant reactor

To help you understand the waste tire pyrolysis plant reactor better, please have a look at :

Till now we have successfully installed our project in more than 30 countries all over the world. Such as Romania, Macedonia, Albania, Turkey, Iran, India, Pakistan, Bangladesh, Thailand, Malaysia, Ecuador, Mexico, Guatemala, Nigeria,Egypt, Hiati, Italy, Poland, etc.Here are some pictures of the same design of reactor in our customers’ factories in different countries

Our enginer and customer

Waste tire pyrolysis plant installed

If you need help in waste tire pyrolysis plant, welcome to contact us at any time.

And we have demo machines in our factory,welcome your visit at any time

| Technical parameter of waste tire pyrolysis plant reactor | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

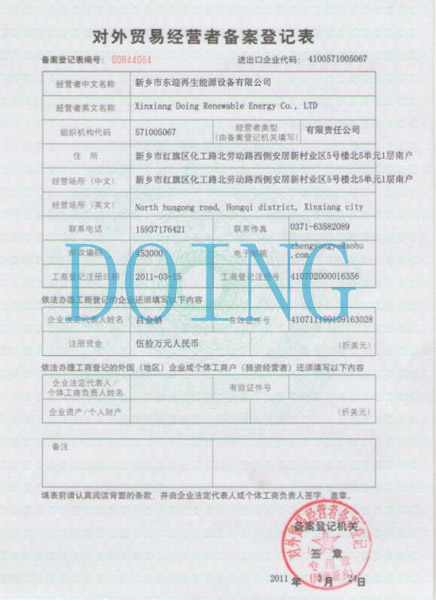

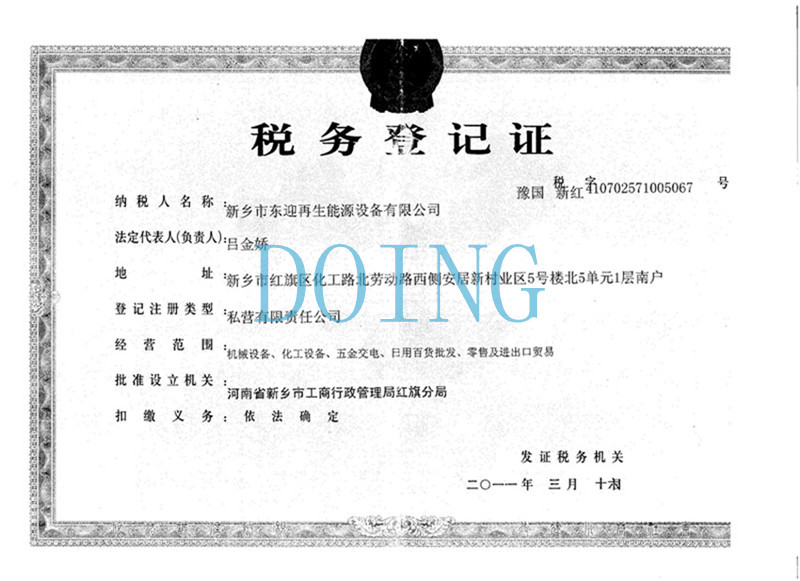

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd