Pyrolysis plastic to oil machinery product introduction

Pyrolysis waste plastic to oil machinery

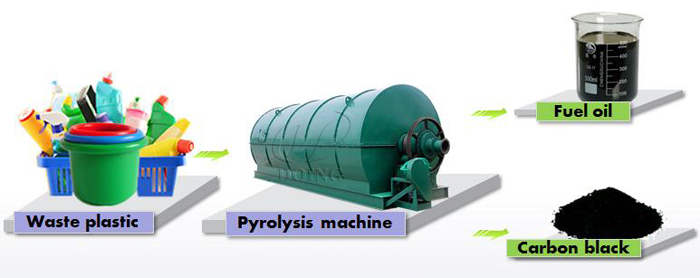

Pyrolysis plastic to oil machinery, also known as waste plastic to fuel conversion pyrolysis plant, can transform various waste plastics like polyethylene, polystyrene, and polypropylene into oil under high temperature and oxygen-free conditions. Currently, DOING's plastic to oil machinery for sale is highly favored by waste plastic recyclers and investors.

1. Why is Pyrolysis Plastic to Oil Machinery Popular for Waste Plastic Recycling?

Pyrolysis plastic to oil machinery is a plant that can extract fuel oil, syn-gas, and carbon black from waste plastic. Typically, 10 tons of waste plastics can yield 3-8 tons of plastic pyrolysis fuel oil, which can be further refined into non-standard diesel through distillation technology. The entire process of plastic to oil machinery meets environmental standards in various countries. Therefore, the waste plastic to oil pyrolysis system not only effectively addresses plastic pollution but also produces valuable potential resource—fuel oil. Given the significant global annual volume of waste plastic and the rising international oil prices, waste plastic refining has emerged as one of the most promising industries.

Pyrolysis waste plastic to oil machinery and final products

Note: PET plastic and PVC plastic are not suitable for pyrolysis into fuel oil due to the production of toxic gases harmful to human health and the environment, along with low oil yield rates.

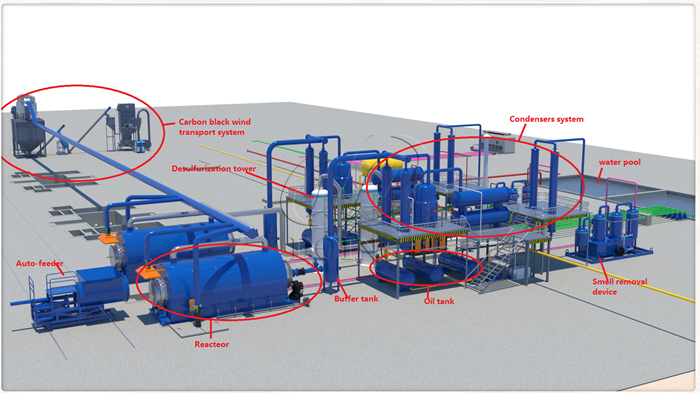

2. Equipment Components of Pyrolysis Plastic to Oil Machinery

Equipment components of pyrolysis plastic to oil machinery

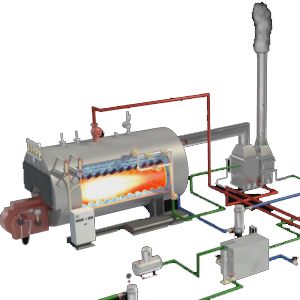

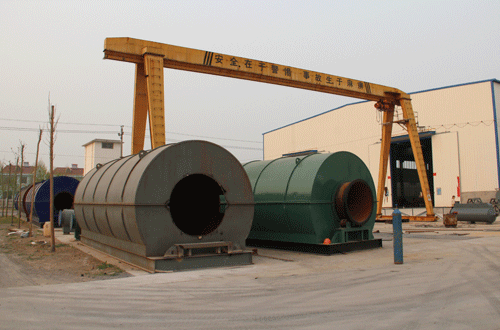

A complete pyrolysis plastic to oil machinery comprises a feeding system/auto-feeder, plastic pyrolysis reactor, oil gas condensation devices, carbon black discharging system, safety devices and advanced environmental exhaust gas purification system, which will guarantee the safe, energy saving and stable operation of pyrolysis plastic to oil machinery. We offer personalized configuration solutions tailored by our professional sales and engineering teams to meet the specific needs of each customer.

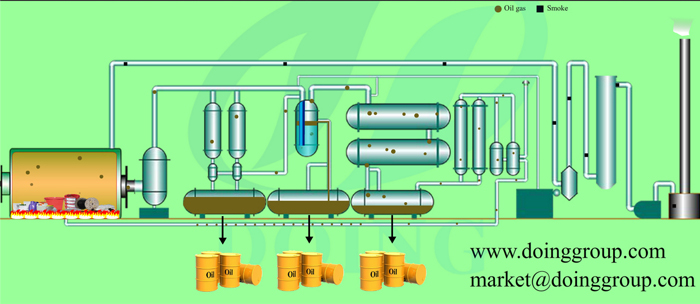

3. Working Process of Pyrolysis Plastic to Oil Machinery:

Flow chart of pyrolysis plastic to oil machinery

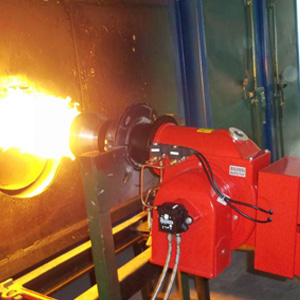

(1) Introduce raw materials into the reactor using the auto-feeder and heat the reactor with fuel sources such as coal, wood, natural gas, or oil. Maintain continuous heating until the temperature reaches around 250 degrees Celsius, causing the waste plastic to convert into oil gas.

(2) Condense the liquid oil from the oil gas using a condenser and collect it in an oil tank. Recycle the exhaust gas, unable to cool at normal pressure, to heat the reactor, thereby conserving energy and safeguarding the environment.

(3) Treat the smoke emitted during tire processing to meet national emission standards through dual desulfurization and dust removal.

(4) Once oil is obtained, automatically discharge the carbon black when the temperature drops below 50 degrees Celsius, marking the completion of one plastic to oil pyrolysis process. You can then proceed with another batch.

4. Pyrolysis Plastic to Oil Machinery Final Product and Applications:

Waste plastic pyrolysis oil applications

(1)Fuel Oil (30% to 80%): The primary application of oil products from our waste plastic to oil pyrolysis machinery is as fuel oil. This versatile product finds use in industrial and commercial settings, including power plants, industrial boilers, furnaces, glass factories, cement factories, and ceramic factories, replacing traditional fossil fuels. The pyrolysis to oil yield mainly depends on the types of waste plastic raw materials.

(2)Exhaust Gas (About 10%): Approximately 10% of pyrolytic gases are generated during the process, primarily composed of methane (CH4). These gases are utilized to heat the plastic to oil pyrolysis reactor, reducing fuel costs, and can be applied to other heating processes as well.

5. Pyrolysis Plastic into Oil Machinery Parameter

To meet different customers' demand, we Henan Doing Company have designed different capacities and different models of pyrolysis plastic to oil machinery for sale. You can choose the machine according to the capacity as well as your budget. If you have any special requirement about the machine, we can also customize the plastic to oil pyrolysis machine for you.

Henan Doing Company Group has been devoted to the R&D, fabrication, export and installation of waste to fuel oil pyrolysis machinery since 2011. Our pyrolysis machinery products have been exported to 100+ countries and regions all over the world till now, such as the United States, Russia, Romania, Thailand, Kenya, Ecuador, China, India, Mexico, Australia, Nigeria, Italy, South Africa, etc. If you want to know more information about the pyrolysis plastic to oil machinery, please contact us. We look forward to cooperating with more customers.

| Technical parameter of pyrolysis plastic to oil machinery | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

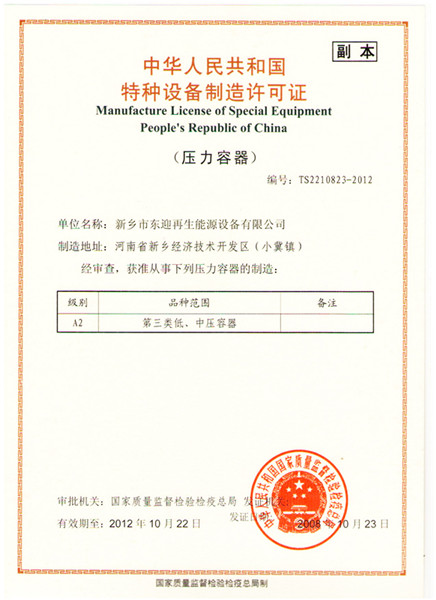

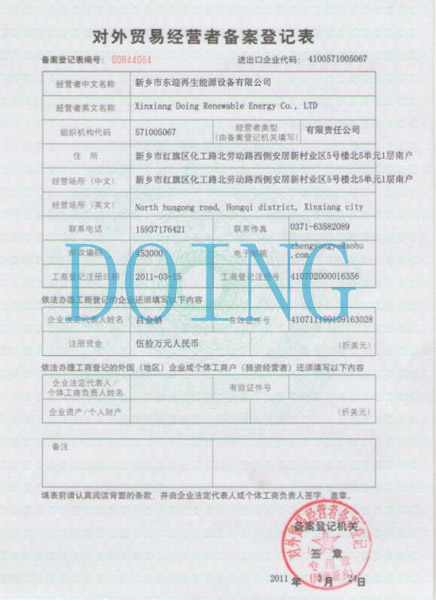

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd