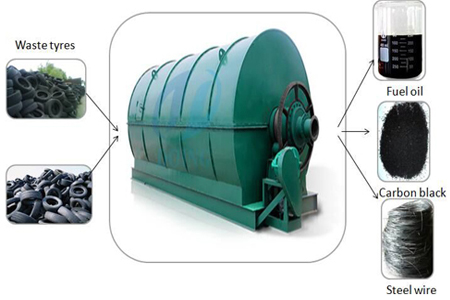

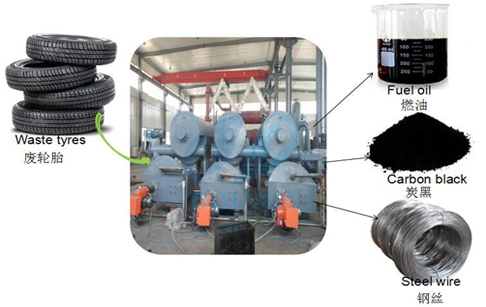

The 8T waste tyre pyrolysis plant product introduction

Type: DY-1-8

Daily Process Capacity: 8T scrap tires/24h

Reactor Size: D2200mm*L6600mm

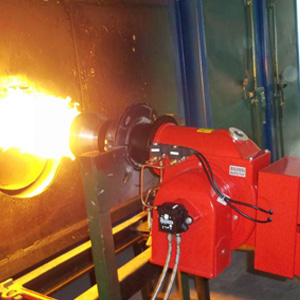

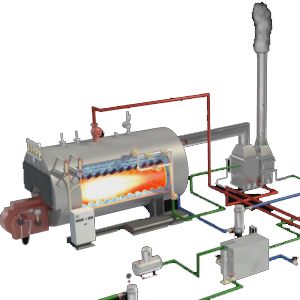

The whole pyrolysis plant composite by total 11 parts, those are reactor ,driving device ,vertical catalytic chamber, cooling tube, oil and water separator ,condenser ,heavy oil tank ,light oil tank , anti-back fire device vacuum system and dedusting device..

Reactor is one of the most important components of the pyrolysis plant. The material and welding technology of reactor will have a direct impact on safety and durable life. To increase the life of the machine, we use auto welder .The welding seam will get X-ray detection and heating treatment .The sealing technology has a very good effect on the safety when we operate the plant.

Inner the condenser there are total 53 pipes. The diameter is 48mm of each. The stylish design enlarges the area of cooling and improves the oil yield rate. Heat exchanging area is about 13 square meter; the total heat exchanging area is 40 square meter to get the best temperature and the largest area for oil gas liquefied.

Vacuum system will guarantee no oil gas leak, safety, and environment protection and energy saving. What is more the vacuum system will improve the oil yield rate. For the same raw material, in the same temperature, the vacuum system will improve the oil yield rate. We will get more oil if we have the vacuum system. With the vacuum system we need lower temperature for the reaction. The vacuum system improves the oil yield rate and makes the pyrolysis system more energy-saving.

Dedusting system will remove ash and impufities in the waste gas.Thus the waste gas will be very clear,when oil as goes into the dedusting system we process the waste oil then the oil gas will be very clear with no pollution to the environment.

| Technical parameter of the 8t waste tyre pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

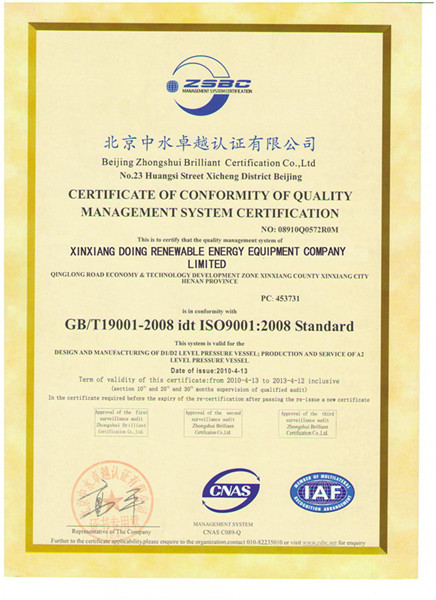

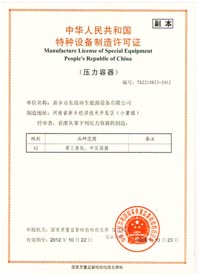

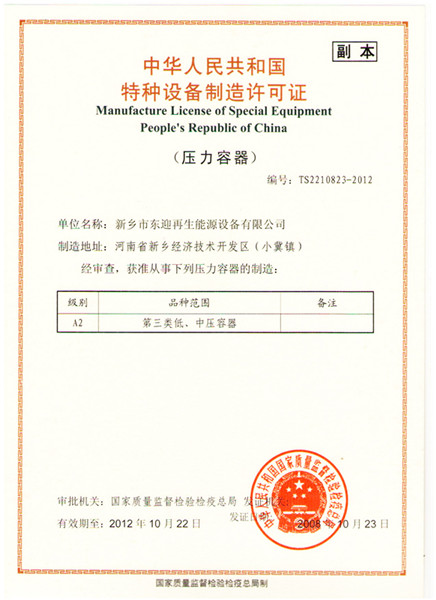

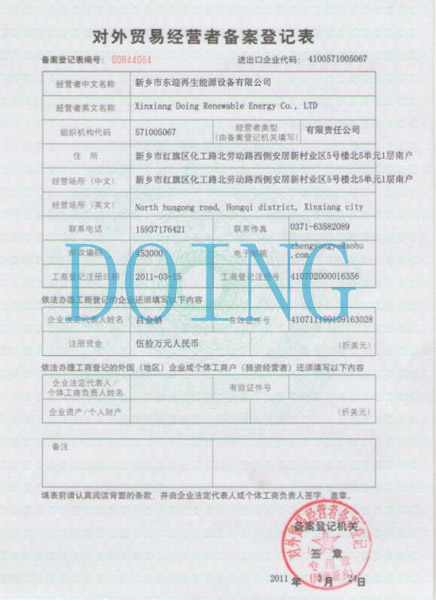

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd