Doing pyrolysis plant product introduction

1.What is waste tyre/tire pyrolysis equipment/plant?

Doing waste tyre/tire pyrolysis equipment/plant is a machine can pyrolysis waste tires,waste rubber and waste plastic,processing fuel oil, crude carbon black and steel wires without pollution.

2.What's the raw material?

That the raw material can be produced to fuel oil, carbon black and steel with wate tyre pyrolysis plant are waste tyre/tires, waste plastic, rubber etc.

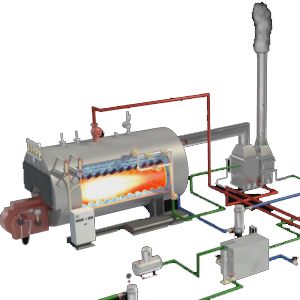

3.How does Doing pyrolysis plant pyrolyze?

Firstly, put the raw material into furnace

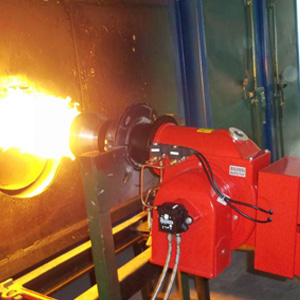

Secondly, burn the fuel material(coal, or wood, or natural gas, or oil ) in the combustion system.

After finishing oil producing, the temperature of reactor will come down, at the same time, carbon black will be discharged automatically.

Lastly, when the temperature falls to 100 degree celsius, worker could open the door of the reactor to discharge the steel wire, then can start another batch.

4.What can we get from the tire pyrolysis machine?

Take waste tire oil refining equipment processing 10 tons for example

No. | Item | Cost of Per Batch |

1 | 10 tons of waste tires | 10T脳USD 236/T=USD2360 |

2 | 0.4 tons of coal | 0.4T脳USD126 /T=USD50.4 |

3 | Water and electricity | 200脳USD0.16=USD32 |

4 | Workers Salary | 4脳USD16=USD64 |

5 | Total Cost | USD2506.4 |

NO. | Item | Income |

1 | Crude Oil | 10T脳45%脳USD709=USD3190.5 |

2 | Carbon Black | 10T脳35%脳USD82=USD287 |

3 | Steel Wire | 10T脳13%脳USD34=USD450 |

4 | Gross Profit | USD3927.5 |

5 | Daily Net Profit | USD3927.5-USD2506.4=USD1421.1 |

6 | Monthly Net Profit | USD1421.1脳25=USD35527.5 |

7 | Yearly Net Profit | USD35527.5脳10=USD 355275 |

5.What's the feature of Doing pyrolysis plant?

Safety:

1. With an auto welding machine for the reactor, it can not only greatly improve working efficiency but also guarantee the quality of welding seam, thus avoid explosion caused by gas leak.

2. Professional heating treatment and x-ray detection chamber are especially for welding.

3. Vacuum system will prevent oil gas from going back to reactor and causing accident.

4. Professional thermometer, pressure gauge and safety valve.

5. It is dangerous to burn exhaust gas (C1 to C4) without any safety measures. In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Environment friendly:

1. Well water dedusting system can avoid black smoke.

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3. Every junction of the reactor is in good sealing situation with professional sealing material.

Long service life:

1. Material: Q245R special steel plate, thickness 14mm.

2. Welding: Automatic welding machine with heating treatment and x-ray detection will prolong the service life of reactor to the max.

3. The service life of the reactor will be 8 -10 years

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

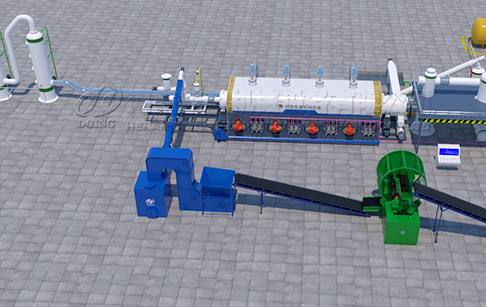

| Technical parameter of doing pyrolysis plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste tyre, waste plastic, waste rubber, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

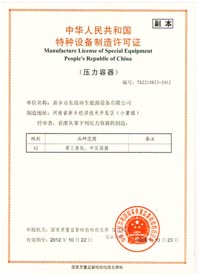

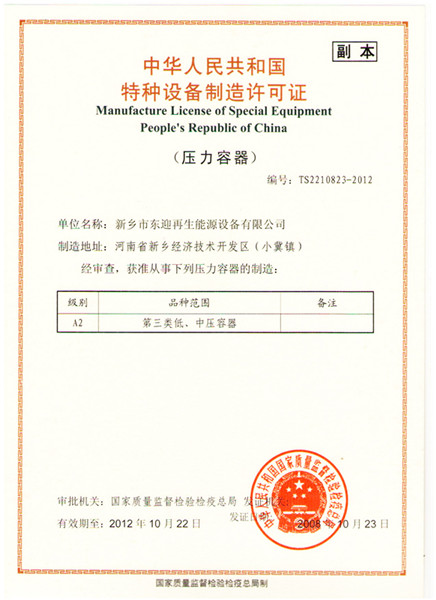

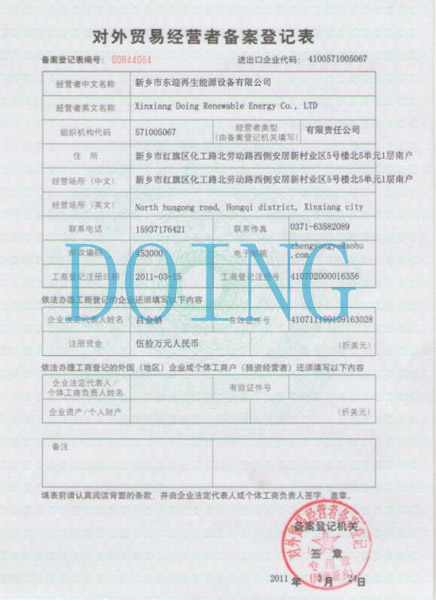

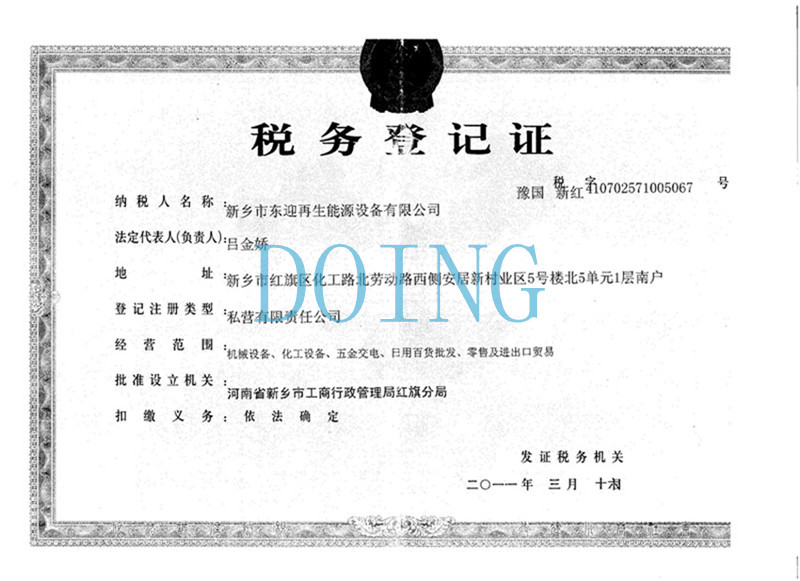

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd