Company news / DATE:2018/10/15

Congratulations to Heilongjiang customers' 12T/D waste tyre to oil pyrolysis plant was smoothly delivered last week.

12T/D waste tyre to oil pyrolysis plant delivered from our factory

Heilongjiang customer operated an old design waste tyre to oil pyrolysis plant before he came to purchase the newest design from us. Through the operation of his old design waste tyre to oil pyrolysis plant, they got extensive industry experience. The main reason why the customer decided to buy the waste tyre to oil pyrolysis plant from us is mainly because our professional shell and tube condensing system is much more efficient than the old-fashioned coil-type cooling system.

12T/D waste tyre pyrolysis plant 3 stage cooling system

And in order to research and confirm the effect of our shell and tube condensers are better than the old design coiled pipe cooling system, the customer spent half a year and visited 3 times to different suppliers, finally decided on us in the last time.

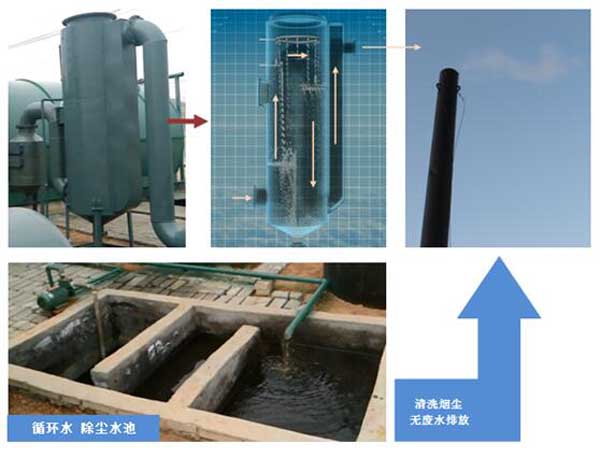

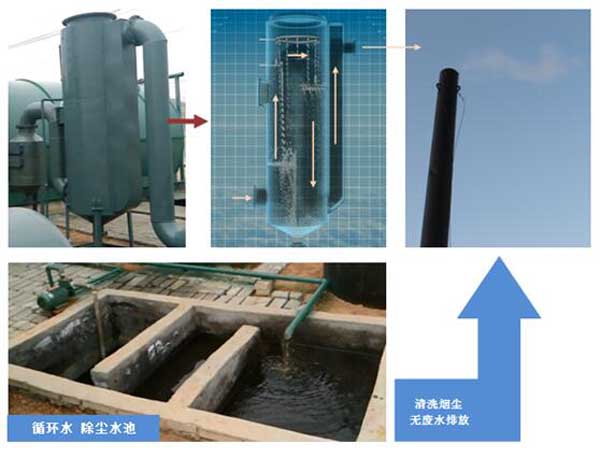

Environmental protection system

Except the cooling system, the environmental protection is also very important by operating the waste tyre to oil pyrolysis plant. For us, we have both tail gas cleaning and smoke cleaning system equipped with the waste tyre to oil pyrolysis plant, thus to ensure no emission to air. And all the water used in the pyrolysis process is for circulation use, therefore no waste water discharge.

12T/D waste tyre to oil pyrolysis plant parts

Any interests to our high environmental protection waste tyre to oil pyrolysis plant, welcome your contact for details.

Inquiry more 12t/d waste tyre to oil pyrolysis plant delivered to heilongjiang province, china information

Leave a message in the below form to get more information about pyrolysis plant project, our engineer will contact you ASAP to analysis pyrolysis plant project cost for you.

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd