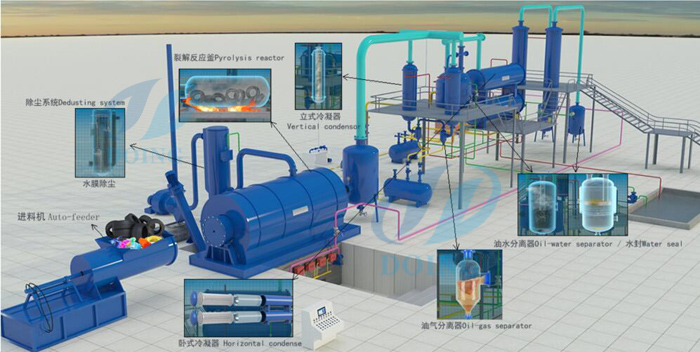

Plastic to oil machine

Doing produced plastic to oil machine transforming non - recycled plastic into a valuable commodity, and creating a reliable source of alternative energy from an abundant, no - cost feedstock.

Plastic to oil machine

Plastic to oil machine ?

Plastic to oil machine working process

Step -1

Put plastic material into the pyrolysis reactor by mechanical feeding machine or manual, then it is delivered into the store bin with the help of conveyor belt. Then, close the feeding door and open heating system of the machine.

Step – 2

In this step, two stages are there in the process. The primary stage: the heat energy needs to start with 100 degree Celsius and ending with 250 degree Celsius. In 100 degree Celsius, the oil gas will release and in 120 degree Celsius the liquid oil will release. The secondary stage: the heat energy needs to change from 250 degree Celsius towards 280 degree Celsius; it is the peak output rate. The oil gas will be collected into the manifold, and the oil as well as the weighty particles are accumulate and dissolved in the center of the manifold and drop into the deep oil container (oil tank). And the lighter oil gas will certainly go up to multifunctional oil condensers to liquefy into oil and keep in the tank.

Step – 3

Cool down the plastic to oil machine after the completion of Step-1 and Step-2. Once the heat reaches about 40 degree Celsius, the carbon black will be discharged automatically.