Waste tyre recycling process plant

With the development of the whole society, more and more cars appear in our life, along with those, more and more waste tyres also appear. But how to deal with those waste tyres without pollution has been a problem. To solve this problem, we Doing group produce the waste tyre recycling process , which can convert waste tyres to oil, carbon black and steel wire.

How to remove oil from waste tyre?

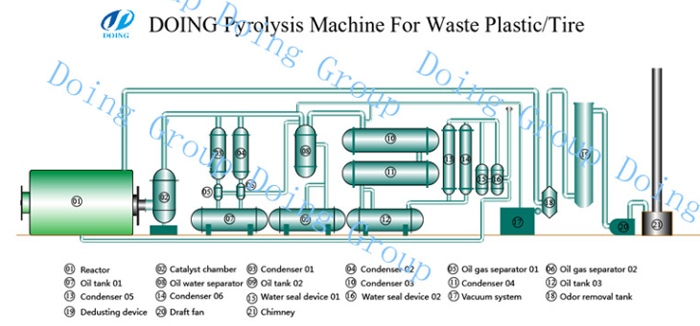

Waste tyre recycling process plant working process

First, the waste tyres are put into the reactor and seal the doors in the reactor

Second, start the waste tyre recycling process plant reactor will rotating and be heated. When the inside temperature reaches the degree of 250 to 280, the oil gas will begin to generate while flow through oilgas separator, and continuously produce until the temperature up to the degree of 350 to 460.

Third, in oil gas separator, light component will enter the condensers, meanwhile, heavy component will be liquefied and then automatically discharged into heavy oil tank.

Forth, most of the light component will be liquefied through condensers to crude oil.

Small amount of oil gas cannot be liquefied and will be transferred by water seal tank back to the burning.